Reading List 08/09/2025

Microplastics in the air, the Blanchard lathe, the report on the OceanGate sub disaster, a plan to visit a black hole, and more.

Welcome to the reading list, a weekly roundup of news and links related to buildings, infrastructure, and industrial technology. This week we look at microplastics in the air, the Blanchard lathe, the report on the OceanGate sub disaster, a plan to visit a black hole, and more. Roughly 2/3rds of the reading list is paywalled, so for full access become a paid subscriber.

Some housekeeping items:

IFP is partnering with Matt Yglesias to solicit ideas for improving federal mass transit policy. If you have an idea for improving mass transit policy, submit a proposal here.

I had planned to publish a piece on the nature of technological progress this week, but it didn’t quite come together the way I hoped, so I’m currently reworking it.

Spinlaunch

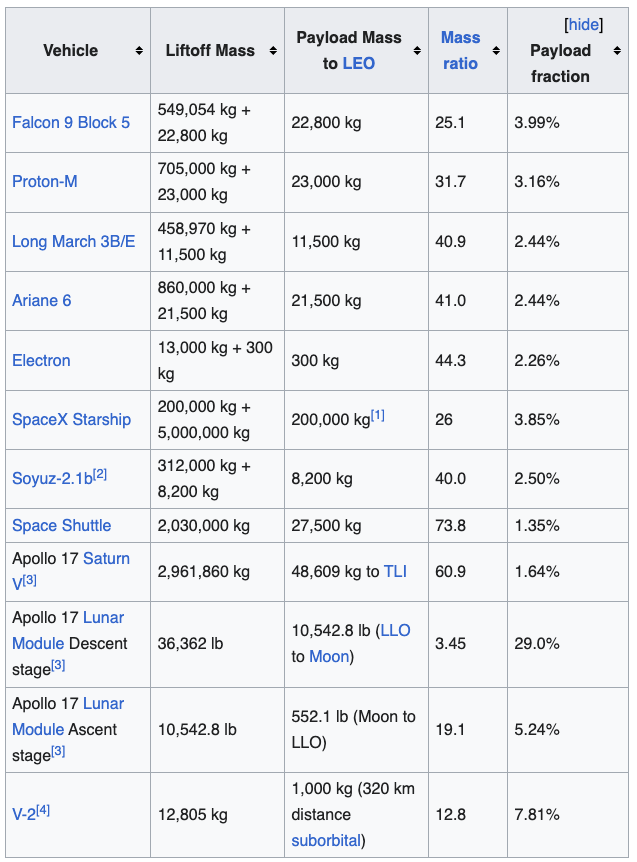

Rockets are a difficult way of putting objects into space. In addition to the technological difficulties inherent in controlling an exploding river of hot gasses, rockets have the unfortunate property that each additional bit of mass launched requires more fuel to lift it, which then requires more fuel to lift that fuel, and so on (a mechanism described as the tyranny of the rocket equation). The result is that rocket payload fractions are a single digit percent of total rocket mass.

There’s thus perennial interest in finding ways to put objects into orbit other than using rockets. One such idea is to use a huge gun to launch a projectile into orbit. This idea has a long history (it’s used to launch a spacecraft in Jules Verne’s 1865 From the Earth to the Moon), and there have been various attempts to build a gun that could launch a projectile into space.

A current attempt to launch a projectile into space is Spinlaunch which, per the name, wants to launch satellites using a huge centrifuge. (This doesn’t completely eliminate the need for a rocket, but will apparently greatly reduce the fuel requirements.) Wired has a long profile of the company:

The idea that an object weighing thousands of pounds can punch its way into space after spinning in circles on Earth’s surface can be hard to fathom. It might even sound crazy, and the company has a lot to prove to shake its critics. So far it has managed to spin an 11-pound dummy payload at more than 4,000 mph and send it crashing into a steel wall. Between those tests and the edge of space, however, are roughly a hundred miles and a whole lot of air resistance. Never mind the engineering work needed to build a centrifuge 100 yards wide, with an arm strong enough to support a roughly SUV-sized rocket.

Yaney hopes this is the year he achieves vindication. The company plans to conduct its first suborbital launches this winter at a new test site in New Mexico. Assuming the system works, Spinlaunch promises to reduce the cost of sending small satellites into space by a factor of almost 20. But the bigger deal may be its launch cadence. Yaney predicts the mass accelerator will be able to do five launches a day; most rocket companies can’t do that many launches in a month. In the era of mega-satellite constellations, which will see thousands of small satellites sent to low Earth orbit over the next decade, Yaney believes Spinlaunch’s time has come.

Ozimek on the US car industry

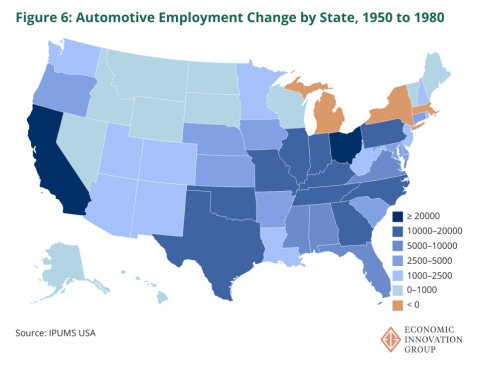

Adam Ozimek of the Economic Innovation Group has an interesting paper on the evolution of the US auto industry, and whether it needs protection from foreign competition. Among other things, he argues that despite common perception, the industry hasn’t collapsed: output has been steady by number of cars and has greatly increased by value add. Rather, it was Detroit specifically that collapsed, as car manufacturers moved production to elsewhere in the US:

The historical record paints the picture. Henry Ford II announced in 1950 that his company’s investments would no longer be concentrated in their established industrial centers. By the mid1960s, Ford had made major investments not just in the southern states of Alabama, Tennessee, and Georgia, but also in New York and New Jersey.

For its part, GM made investments in Indiana, Ohio, Illinois, New Jersey, Mississippi, and

California, while Chrysler invested in New York, Delaware, Indiana, and Ohio — all by the late 1950s.

These investments and the jobs that followed them did not occur as a result of foreign car companies establishing their factories in the south and other parts of the country. That came much later. Long before the Big 3 were seriously challenged by foreign automakers, they themselves had begun decentralizing auto investment out the industrial hub of Michigan and spreading jobs and investment across the rest of the country.

So globalization couldn’t kill Detroit because Detroit was already dead. Or at least dying.

And it really was a story of decline in Detroit almost exclusively. From 1950 to 1980, auto

employment even in most of the Rust Belt states expanded. The gains in Ohio, Indiana, and Illinois exceeded those of any southern state.

Air microplastics

An occasional topic of interest around here is indoor air quality: I’ve previously written about how UV light could be used to help prevent future pandemics by killing airborne pathogens, and whether there are negative cognitive effects from carbon dioxide.

This PLOS ONE paper has put another indoor air pollutant on my radar: microplastics. From the abstract:

The ubiquitous presence of airborne microplastics (MPs) in different indoor environments prompts serious concerns about the degree to which we inhale these particles and their potential impact on human health. Previous studies have mostly targeted MP in the 20–200 µm size range, which are less likely to efficiently penetrate into the lungs. In this study, we specifically investigate airborne, indoor suspended MPs in the inhalable 1–10 µm (MP1–10 µm) range in residential and car cabin environments, by using Raman spectroscopy. The median concentration of total suspended indoor MPs for the residential environment was 528 MPs/m3 and 2,238 MPs/m3 in the car cabin environment. The predominant polymer type in the residential environment was polyethylene (PE), and polyamide (PA) in the car cabin environment. Fragments were the dominant shape for 97% of the analyzed MPs, and 94% of MPs were smaller than 10 µm (MP1–10 µm), following a power size distribution law (the number of MP fragments increases exponentially as particle size decreases). We combine the new MP1–10 µm observations with published indoor MP data to derive a consensus indoor MP concentration distribution, which we use to estimate human adult indoor MP inhalation of 3,200 MPs/day for the 10–300 µm (MP10–300 µm) range, and 68,000 MPs/day for MP1–10 µm. The MP1–10 µm exposure estimates are 100-fold higher than previous estimates that were extrapolated from larger MP sizes, and suggest that the health impacts of MP inhalation may be more substantial than we realize.

Note that I haven’t read this paper closely, and these sorts of findings sometimes turn out to be overblown or incorrect. (Cremieux notes, for instance, that a widely-referenced paper blaming asthma on gas stoves turned out to be incorrect.) But particles in the air will in general cause health problems, so if there are many more plastic particles in the air than previously realized that seems likely to be bad.

Blanchard lathe

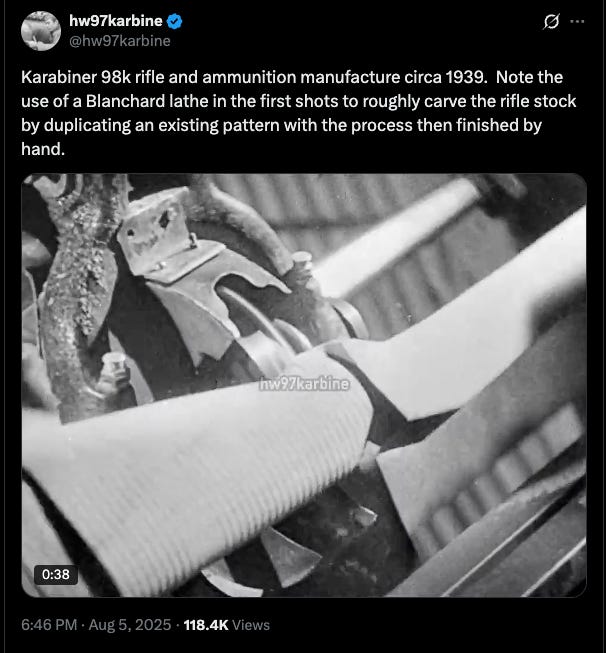

If you read much on the history of American invention, you’ll quickly come across mention of the Blanchard lathe, a clever invention made in the early 19th century for manufacturing gunstocks. The lathe used an existing gunstock as a cam mechanism: as the existing gunstock rotates, it pushes against a movable arm connected to a saw. The path of the saw movement matches the shape of the existing gunstock, and can cut a piece of wood into the same shape.

Most discussions of the lathe only mention its invention, but apparently such lathes remained in use well into the 20th century. On Twitter, hw97karbine posts a video of a Blanchard lathe being used to manufacture the stock for a German Karabiner 98k around 1939.