Reading List 12/20/25

Tesla’s robotaxi crash reports, a fusion startup merger, the decline of US injection molding, Wyoming’s snow fences, and more

Welcome to the reading list, a weekly roundup of news and links related to buildings, infrastructure and industrial technology. This week we look at Tesla’s robotaxi crash reports, a fusion startup merger, the decline of US injection molding, Wyoming’s snow fences, and more. Roughly 2/3rds of the reading list is paywalled, so for full access become a paid subscriber.

TAE Technologies merges with Trump Media Group

Here’s a merger I didn’t see coming: TAE Technologies, one of the current crop of fusion energy startups (and one of the ones that has raised the most funding after Commonwealth Fusion) is, for some reason, merging with the Trump media group (the parent company of Truth Social). From the Financial Times ($):

The Trump family media group has agreed to combine with Google-backed fusion energy company TAE Technologies in a deal valued at $6bn, representing a bet on nuclear energy powering the artificial intelligence boom.

The all-stock deal will merge Trump Media & Technology Group’s access to capital with TAE’s fusion technology in an effort to meet the soaring power demands of AI, the two groups said on Thursday.

The unusual deal highlights the changing nature of dealmaking in America under US President Donald Trump. It brings together two industries rarely seen at the same table: Trump Media, built on right-leaning online politics, and a Google-backed fusion company rooted in Silicon Valley’s long bet on breakthrough energy tech.

The combined group plans to start construction in 2026 on what they described as the world’s first utility-scale fusion power plant. They initially plan a 50MW facility and later up to 500MW.

At Bloomberg, Matt Levine describes this as taking advantage of Trump Media’s ability to sell stock in the absence of anything resembling a profitable business:

…if the CEO of TMTG sat down with the CEO of a NUCLEAR FUSION COMPANY and got to talking about combining their businesses, a conversation like this would not make a ton of sense:

TMTG: We operate a social media site and we’re getting into anti-woke exchange-traded funds. Our mission is to “end Big Tech’s assault on free speech by opening up the Internet and giving people their voices back.”

Nuclear fusion company: Cool that sounds fun. We are working on smashing atoms into each other to generate power.

TMTG: Huh, we should team up. Maybe our social media site can give you tips on how to smash atoms, or we can cross-sell your electricity to our anti-woke ETF customers.

Nuclear fusion company: What.

Whereas a conversation like this has an obvious logic:

Nuclear fusion company: We do fusion stuff, we’ve raised $1.3 billion of capital from investors like Google and Chevron, but we need more money to build fusion power plants.

TMTG: Oh people love giving us money, we should get together.

Tesla crash reports

Data on the crash frequency of Waymos suggests that Waymos are much, much safer than human drivers (to the point that some people are calling for widespread adoption specifically as a public health measure). The same does not seem to be true for Tesla’s robotaxis. Via Electrek:

While a few fender benders might not seem like headline news, it becomes significant when you look at the math.

Last month, Tesla confirmed the fleet had traveled roughly 250,000 miles. With 7 reported crashes at the time, Tesla’s Robotaxi was crashing roughly once every 40,000 miles (extrapolating from the previously disclosed Robotaxi mileage).

For comparison, the average human driver in the US crashes about once every 500,000 miles.

This means Tesla’s “autonomous” vehicle, which is supposed to be the future of safety, is crashing 10x more often than a human driver.

While Tesla’s Robotaxi fleet reportedly increased in November, with the number of cars spotted going up to 29, there’s no evidence that the Robotaxi mileage increased. In fact, the utilization rate indicates Tesla is running only a few vehicles at a time – meaning that mileage might have actually gone down.

Electrek’s data for human crash frequency seems to be wrong — per AAA analysis of US DOT data, it seems to be closer to around one crash per 100,000-200,000 miles or so — but Tesla still seems worse than human drivers.

iRobot declares bankruptcy

I once chatted with someone considering founding a robot startup who said that the challenge with robots is that it’s hard to get to a huge market with many millions of potential customers. They pointed to iRobot as one of the only robotics companies that had tapped into a really huge market, with robotic vacuums. So it’s noteworthy to me that iRobot is now declaring bankruptcy. Via Bloomberg:

iRobot Corp., the company that revolutionized robot vacuum cleaners in the early 2000s with its Roomba model, filed for bankruptcy and proposed handing over control to its main Chinese supplier.

The Massachusetts-based consumer robot maker, which is currently listed, will be taken over by China’s Shenzhen PICEA Robotics Co. and a subsidiary of the Chinese firm, according to a press release. The company listed between $100 million and $500 million of assets and liabilities in a filing.

The common stock of iRobot, founded in 1990 by engineers from the Massachusetts Institute of Technology, will be wiped out under the proposed Chapter 11 plan filed in Delaware on Sunday.

Shares of the company plunged as much as 75% on Monday, hitting an all-time low.

iRobot enjoyed initial success with the Roomba that it debuted in 2002 and which quickly became synonymous with autonomous vacuum cleaners. But earnings at the firm, which has sold more than 40 million home robots, began to decline in the post-Covid era, hit by supply chain issues and cheaper competitors. The firm warned of potential bankruptcy earlier this month.

In 2022, Amazon.com made an offer that would have turned the company’s fortunes, but it collapsed over a clash with European Union competition authorities.

IEEE Spectrum has a good interview with the former co-founder of the company here.

Bloomberg notes that the merger with Amazon fell apart due to EU issues, but the merger was also opposed by US politicians, which folks have not been shy about pointing out. Via a Reason article from October:

Online retail giant Amazon announced in August 2022 that it had agreed to purchase iRobot, makers of Roomba robot vacuums, for $1.65 billion. The acquisition would expand Amazon’s footprint in the smart home market, after it previously purchased video doorbell company Ring.

The following month, the Federal Trade Commission (FTC) opened an investigation into the merger. Sen. Elizabeth Warren (D–Mass.) and several Democrats in the House of Representatives sent a letter to then-FTC Chair Lina Khan, saying “the FTC should use its authority to oppose the Amazon–iRobot transaction.”

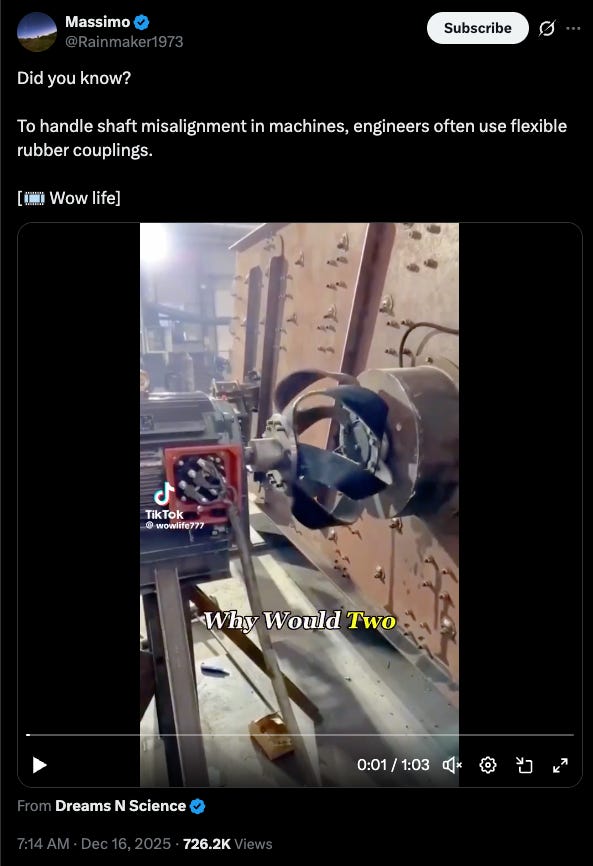

Rubber couplings

One of the recurring themes of my book is the corrosive effects of variability on a production process. Variation in a production process means waste — parts that are outside of tolerance and need to be thrown away or reworked, buffers of material that accumulate between misaligned process steps, and so on.

One strategy I highlight for dealing with variability is to make your process more robust to it, such as by redesigning a part or assembly to allow for larger tolerances. Here’s an interesting example of something like this being used in practice: rubber couplings between machines to allow for shafts that are slightly misaligned.

Parts company McMaster-Carr has thousands of flexible couplings for sale, though these mostly don’t look like rubber bands. Alignment laser system manufacturer Ludeca has a bit more on flexible couplings, recommending (unsurprisingly) that machines only be run temporarily in misaligned conditions:

Some coupling manufacturers will sell couplings claiming that the coupling can take shaft misalignment. While this is true for most flexible couplings, it can be easily misinterpreted. Flexible couplings are designed to withstand, without damage, some shaft misalignment. Sometimes it is perceived that, since the coupling can take the misalignment, the machines can run under this condition without any consequences. When running machinery with significant shaft misalignment, bearing and seal life may decrease immensely, and other damage results. Therefore, for longer machinery life, it is always recommended to have equipment laser aligned to standard industry tolerances for shaft alignment, and not to the looser alignment tolerances allowed by the coupling itself.