Group Technology, the Forgotten Cousin of Lean Manufacturing

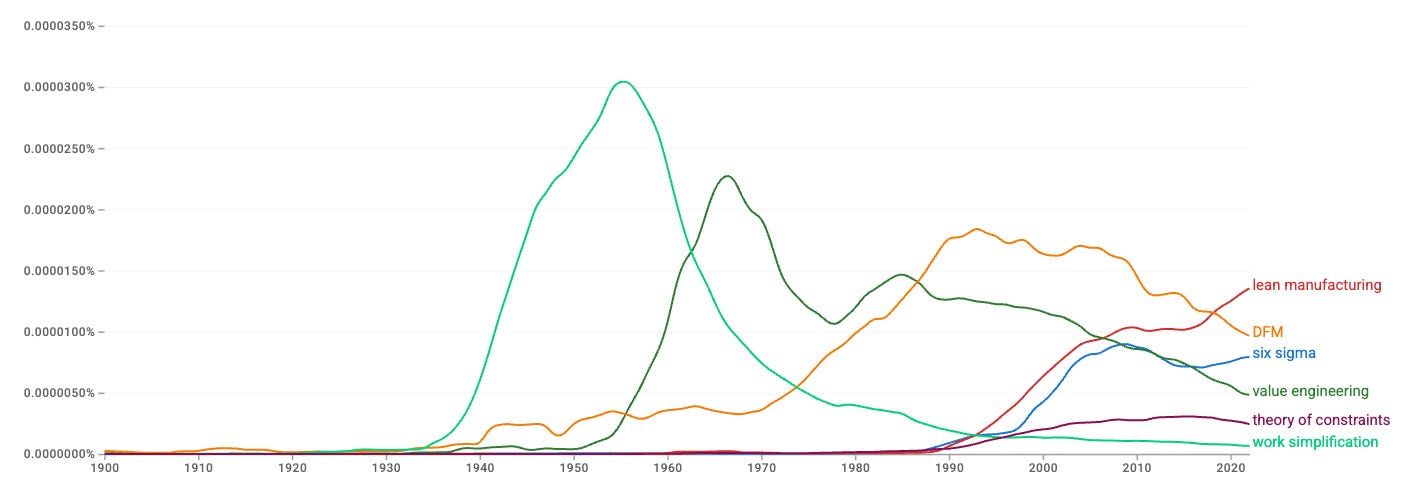

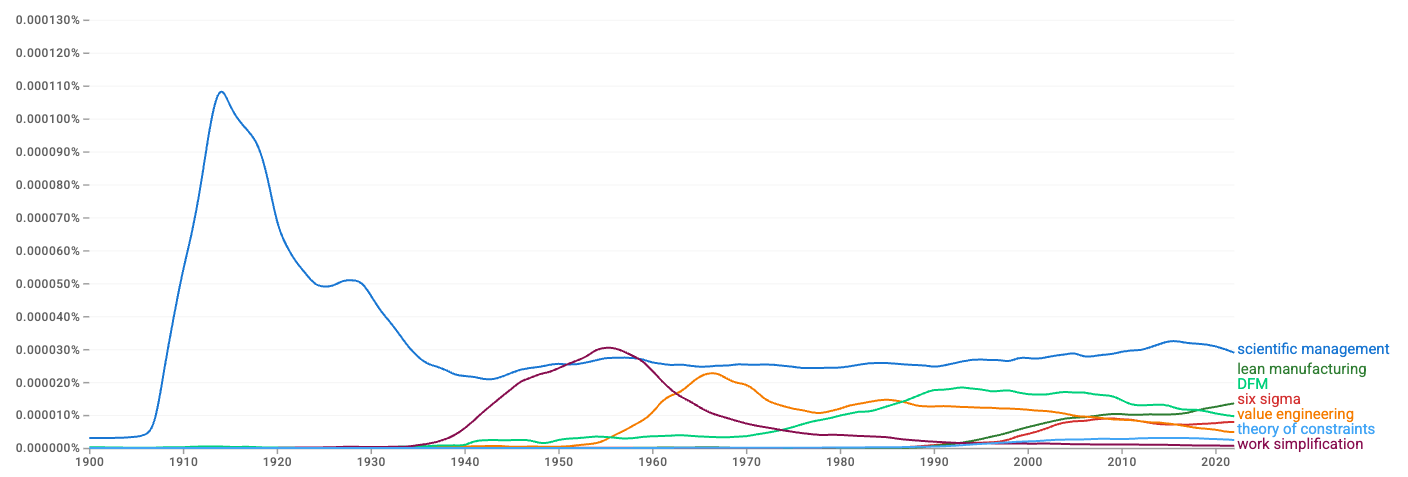

Industrial improvement systems — strategies for making a business more profitable, more efficient, or better operated — rise and fall in popularity over time. Today, the most widely known improvement systems are probably various flavors of “Lean methods," the adaptation of the Toyota Production System first made popular by the 1990 book The Machine that Changed the World. But go back to the 1950s, and efficiency experts will instead tout the benefits of “work simplification," a collection of strategies for streamlining production processes and eliminating wasteful or unnecessary steps. (Work simplification is still occasionally recommended as a method of process improvement today, including by the consultant with the unfortunate website URL www.worksimp.com.) Go even farther back to the turn of the century, and the dominant improvement strategy will now be Frederick Taylor’s scientific management.1

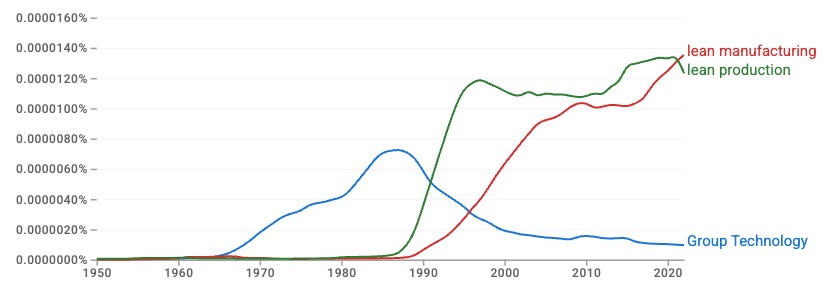

One lesser known industrial improvement system that appeared and then receded in the second half of the 20th century is Group Technology. Group Technology first arose in the Soviet Union, and shares many similarities with Lean methods. But its popularity peaked in the 1980s, and today it seems mostly forgotten. It’s interesting to try and understand what made it seem compelling, and why it ultimately lost favor.

Premise of Group Technology

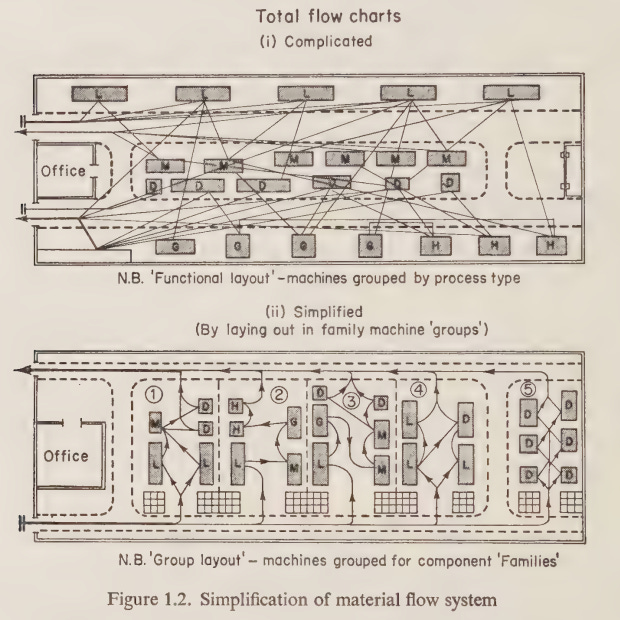

Group Technology is an improvement system designed to apply to factories, machine shops, or other production operations that produce a wide variety of different parts in relatively small numbers. Unlike mass production, which can use dedicated production lines to produce large volumes of identical or near-identical goods, equipment in these high-mix, low-volume operations will be used to produce a variety of different parts or components depending on the day. A machine might be used for Part A today, Part B tomorrow, Part C the next day, and so on.

The basic idea behind Group Technology is that many of the parts and components produced in these sorts of operations will share similarities. A machine shop might make 50 different types of steel bolt, depending on the exact product or the customer’s order, but while the sizes and shapes of the bolts might differ, they’ll likely all use similar materials and require the same sort of operations done in roughly the same order. These similarities can be exploited to make production operations more efficient. In Group Technology, similar parts made from similar materials and that require similar operations are grouped together (hence the name), and produced in manufacturing cells dedicated to those types of parts. These cells contain the exact machines needed, arranged in the order that they’re needed and configured to do the sorts of jobs that the parts require.

This arrangement yields several benefits:

Movement and travel times are reduced. Parts don’t need to be routed all over the factory, but move quickly through a series of machines dedicated to particular groups.

Setup times are reduced. Machines can be configured to quickly perform the sorts of operations a particular group of parts or components requires.

Work in process and cycle times are reduced. With less movement and setup time, products get routed through the necessary steps much more quickly, resulting in less inventory piling up and products getting to the customer much faster. Short cycle times allow for material to be ordered frequently in smaller batches, paced to the level of demand, making it easier to flexibly respond to market changes.

Capital costs are reduced. Less work in process means smaller factories are required, and reduced setup times results in greater equipment utilization, squeezing more output from a given amount of equipment.

More generally, Group Technology aims to achieve many of the benefits of mass production in a high-mix, low-volume production operation.

A brief history of Group Technology

The basic ideas behind Group Technology — creating dedicated production areas for similar sorts of parts — began to emerge in the early 20th century in the wake of mass production, assembly line methods.2 In 1925, American engineer RE Flanders described a method of production control which emphasized “standardization of product, departmentalization by product rather than process, minimized transportation, visual control of work itself instead of remote control by records.’” In 1938, JC Kerr, another American engineer, described grouping machine tools together to “smooth the flow of production as it does in a one-product shop.” And in 1949, Swedish engineer Arn Corling described the reorganization of a Swedish bus manufacturer around principles of what he called “group production”:

He wrote that group production was an adaptation of line production to the machine shops working on batch production and that “this implies radical decentralisation into small independent production units or groups, each comprising the machines and everything needed for the complete manufacture of a special category of parts.”

But it was the Soviet Union where Group Technology as a holistic system of improvement truly emerged. In 1937 Soviet professor AP Sokolovskiy suggested that “parts of similar configuration and features should be manufactured by standard processes, thus making it possible to introduce flow line into batch production.” In 1952, Soviet engineer SP Mitrofanov published a monograph on using ideas of group production on turret lathes, and began consulting with other factories on how the ideas could be adopted. Thanks to Mitrofanov’s efforts (he published four books on what he began to call Gruppovaya Tekhnoiogiya, or Group Technology, between 1955 and 1959), Group Technology began to gain traction in the USSR. Mitrofanov was awarded the Lenin Prize in 1959, and Group Technology was recommended by the Central Committee of the Communist Party. Group Technology became “one of the fashionable new technologies," and it was discussed frequently in seminars and talks. By the early 1960s, Group Technology was being used in hundreds of Soviet factories.

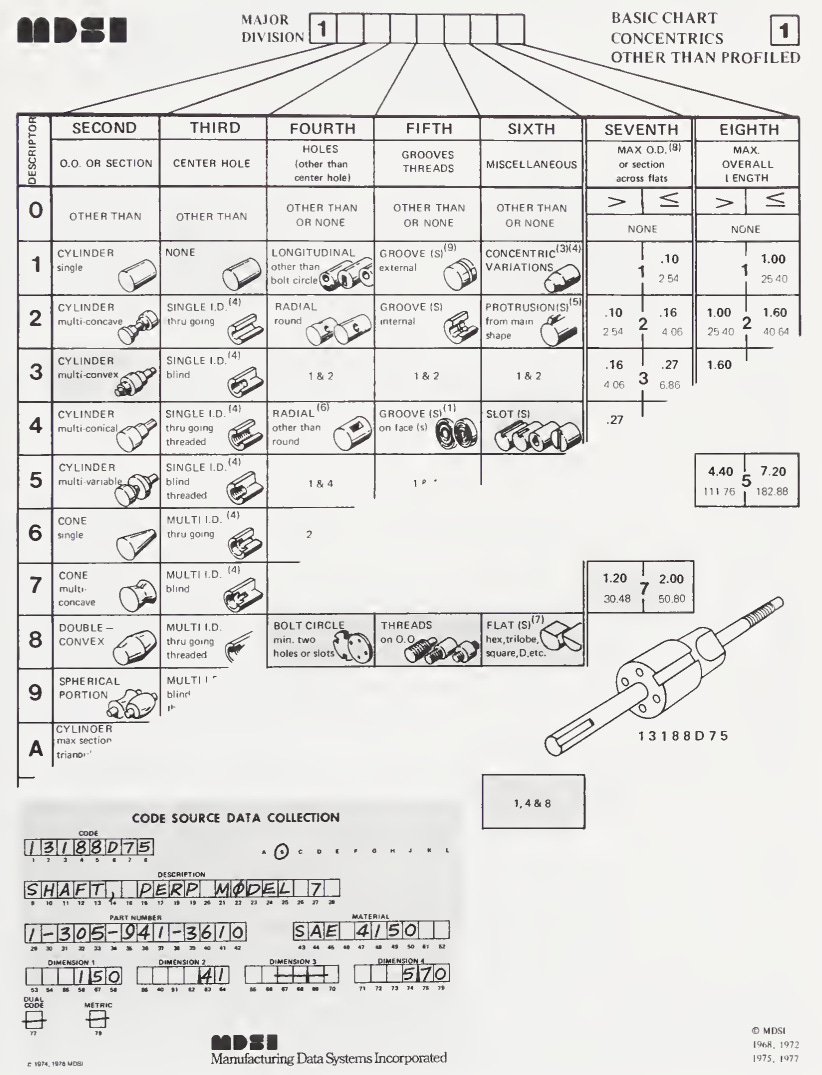

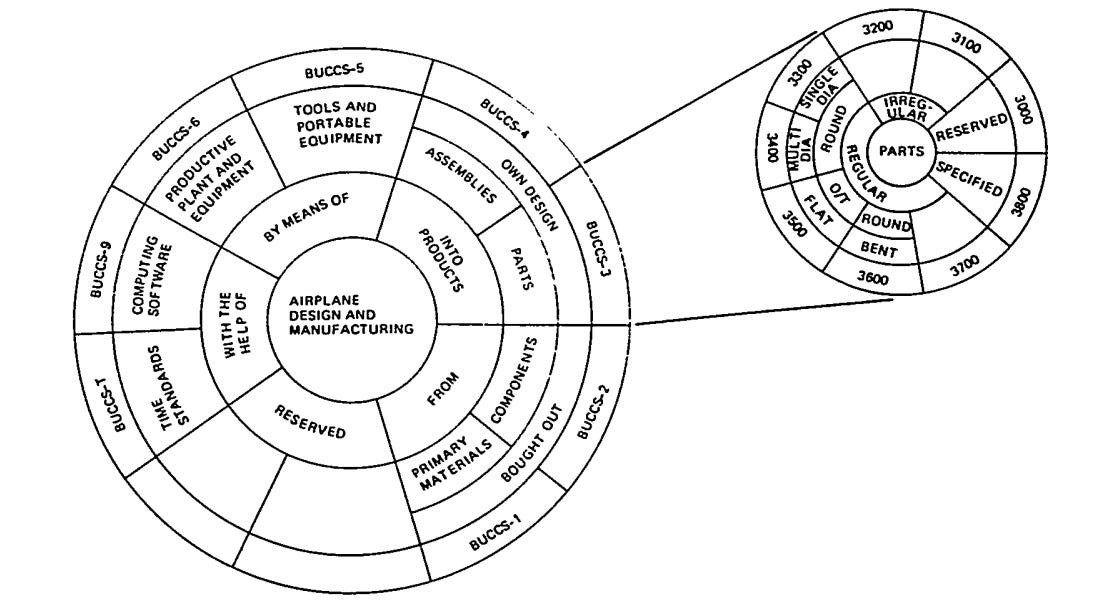

As it spread in the Soviet Union, Group Technology also began to take root in Europe and the US. This seems to have been partly due to broader interest in codification and classification systems that were being developed in the late 1950s and early 1960s, and partly due to Mitrov’s book The Scientific Principles of Group Technology being translated into English in 1966. A conference on Group Technology was held in London in 1961, and it was discussed at a series of international conferences on classification and coding that were held in the 1960s. By the 1970s, there were at least half a dozen books published in English that touted the benefits of Group Technology, and companies like Boeing had adopted the methods in at least some form.

The peak of Group Technology’s popularity seems to have been the 1980s.3 Up through the end of the decade, it continued to be the subject of dedicated books, and merit substantial mentions in books on adjacent subjects (such as just-in-time and flexible manufacturing systems). But interest in the system seems to have rapidly fallen off in the 1990s.

One industry that did, and (as far as I’m aware, still does) enthusiastically adopt Group Technology is shipbuilding. Modern texts on shipbuilding, such as Storch’s Ship Production, still make extensive reference to Group Technology as the system used to divide up work on a ship and in a shipyard. However, it’s not 100% clear to me when this “adoption” actually took place. From what I can see, it wasn’t until the late 1970s, when the US began studying modern shipbuilding methods in countries like Japan via the National Shipbuilding Research Program, that the label of Group Technology began to be applied. Researchers then retroactively described these methods as “working off the logic of Group Technology.”

Why interest in Group Technology waned

It’s not 100% clear why interest fell in Group Technology, but I have some suspicions. Many of the valuable aspects of Group Technology — using manufacturing cells, reducing work in process and cycle times, eliminating wasteful part movements, decreasing setup times, increasing machine utilization — weren’t unique to group technology, but were similarly advocated by other industrial improvement systems like Lean methods and the Theory of Constraints. (Those familiar with Lean methods will note how similar the advertised benefits of Group Technology are to Lean.) And other systems often bundled these benefits into a much sexier package. Lean methods were spread by The Machine that Changed the World, a popularization of Womack and Jones’ academic research on the Japanese Auto industry, which sold in enormous numbers, like The Goal. Both of these books encapsulate their recommendations into an easily digestible format.

By contrast, what’s notable to me when reading about Group Technology is how much emphasis is immediately placed on the tedious process of part coding and classification. It often seems like developing a part coding scheme and the necessary documentation (which might entail creating thousands of new part drawings) is the main thing Group Technology efforts end up focusing on. A 1989 survey of US Group Technology users, for instance, extensively discusses the codification schemes and issues with implementing them, but makes no mention of any benefits achieved in terms of reduction of part movement, setup or cycle times, or machine efficiency (the only benefits discussed relate to part design and process planning). Often this codification seems to have involved buying some off the shelf codification system (along with implementation software), and then adapting it to the needs of the specific business.

Given how much emphasis it places on doing tedious paperwork and software configuration, it’s not surprising to me that there were no breakout Group Technology hits like The Goal or The Machine That Changed The World, or that systems that repackaged many of Group Technology’s basic ideas, without the immense emphasis on paperwork, became more successful.

It was likely the adoption of electricity, which allowed machine tools to have their own dedicated electric motors, which made Group Technology possible. Prior to dedicated electric motors, machines were driven by belts connected to overhead drive shafts, which limited flexibility in machine arrangement. Giving each machine its own motor removed this constraint. (industrial innovation in the soviet union 106).

In general, the 1980s seem to have been a period of high demand for industrial improvement systems, possibly due to falling US competitiveness compared to foreign countries like Japan. In addition to books on Group Technology appearing that decade, Goldratt published The Goal, his bestselling business novel describing the Theory of Constraints. The 1980s is also when interest in Japanese manufacturing techniques really began to take off.

I work in this space, and I often see people try to group parts into “part families” and process them in some sort of bunched manner. The hard part with the whole premise is that tries to optimize high mix, low volume product but that product is too unstable in design or too low volume to see returns on process optimization.

If I run a machine shop and part A comes from customer A and part B comes from customer B, and the parts have a lot of similar operations that need to be completed, grouping them physically as they travel the shop floor requires 1) the upfront planning, 2) clear and similar production runway from customers A and B, and 3) that there’s something to be gained vs just running a bigger batch of each part. Also from a quality perspective, it would be a nightmare to try to actually mix product in a chemical bath or any specific step of a manufacturing process that you would be able to.

Now you could argue that it’s less about batching and more about factory layout, but then I think you get away from the core premise and you’re just back to making simple conclusions like “I should put my deburr station in between my milling and inspection stations.”

The place I think family building does provide a return is if customer A realizes that 10 of their parts are all pretty similar and they give all that work to one machine shop. That machine shop might not literally bunch them along the production process, but their expertise in developing the recipe for one part will extend to the rest and they’ll be able to offer better prices seeing the larger runway and work volume coming their way.

Work Simplification was pushed by the federal government during WWII and lasted a decade or two longer in government than in industry. The same is broadly true of group technology, which was called "layout studies" in the US jargon. It wasn't nearly as developed as in the USSR but nonetheless was definitely important.

The military applied it to arsenals and shipyards, but even the civilian agencies applied it to improving the flow of paperwork through an office. Here's a random brief illustration from a military manual (pg 27–30):

https://www.google.com/books/edition/Work_Simplification/NxQ02QmmywkC?hl=en&gbpv=1&pg=PA27&printsec=frontcover

I've written quite a bit about where work simplification came from and what happened to it. Layout studies were part of the same story. In all cases, of course, these approaches drew upon the quite fleshed out approaches to manufacturing that factories had developed. Perhaps of interest:

https://www.statecapacitance.pub/p/how-the-feds-invented-lean-manufacturing