Reading List 08/16/25

Efforts to stop solar and wind permitting, Ford’s new manufacturing process, Lake Powell’s water levels, Tesla’s used car prices, and more.

Welcome to the reading list, a weekly roundup of news and links related to buildings, infrastructure, and industrial technology. This week we look at efforts to stop solar and wind permitting, Ford’s new manufacturing process, Lake Powell’s water levels, Tesla’s used car prices, and more. Roughly 2/3rds of the reading list is paywalled, so for full access become a paid subscriber.

Some housekeeping items this week:

I’m going to try to keep the plugging to a minimum, but I’ll mention once more that my book, The Origins of Efficiency, is now available for preorder.

Some folks have asked about the high prices for international shipping for the book listed on Stripe’s website; for international orders your best bet is probably to just wait until the book is available on your country’s Amazon page.

I was on Marketplace briefly talking about shipbuilding again.

I was a guest on the World of DaaS podcast.

Solar and wind permitting and capacity density

The US Department of the Interior is apparently still looking for ways to shut down wind and solar construction. A new order from the secretary, SO 3438, questions whether permitting wind and solar projects on federal land is even legal because of how much land they use. From the order:

This Order directs the Department of the Interior (Department), consistent with the Federal Land Policy and Management Act (FLPMA) and the Outer Continental Shelf Lands Act (OSCLA), to optimize the use of lands under its direct management, including the Outer Continental Shelf, (hereafter referred to collectively as “Federal lands”) by considering, when reviewing a proposed energy project under the National Environmental Policy Act (NEPA), a reasonable range of alternatives that includes projects with capacity densities meeting or exceeding that of the proposed project…Ultimately, FLPMA’s multiple use mandate for onshore lands, OCSLA’s multiple requirements for offshore activities, and NEPA’s requirement to consider reasonable alternatives to a proposed action give rise to the question on whether the use of Federal lands for any wind and solar projects is consistent with the law, given these projects’ encumbrance on other land uses, as well as their disproportionate land use when reasonable project alternatives with higher capacity densities are technically and economically feasible.

As Jason Clark of Power Brief notes, “capacity density” is basically a made-up metric created specifically to try and make wind and solar projects look bad, and is not even being applied consistently:

DOI is questioning if *any* wind or solar should be permitted (their emphasis on *any*).

It's all tied back to this new metric called "CAPACITY DENSITY" which is an invented formula to ding projects on a combo of:

1) Capacity Factor (hashtag#AgeofBaseload)

2) Acreage used for a lease

By DOI's estimations the holy grail of Capacity Density is a nuclear AP1000 project with a score of 33.17. In this case higher number = better.

DOI claims that solar, solar+storage, and wind are "too low" on this metric compared to other reasonable alternatives. Of course not accounting for varied capacity factors or multiple uses of land....

The Big Contradiction:

Everything is "low" compared to a nuclear facility -- even a Combined Cycle Natural Gas plant is nearly 9 points "worse."

But the cutoff for what is vs. what isn't an acceptable Capacity Density seems entirely arbitrary.

Take Coal and Geothermal. DOI has taken steps to ENHANCE the permitting for both -- even though their Capacity Density is pretty crappy compared to nuclear, SMRs, and all forms of Natural Gas generation.

There are a thousand other flaws in this…

Some other flaws in this are the fact that only a tiny fraction of the land “used” by a wind project is actually occupied by the turbines, and that land is massively more valuable when used to produce solar power than it would be if it were used for many other widely accepted purposes, such as growing corn. This is also another unfortunate example of how easily the tools of environmental review can be used to harm the environment.

Is air travel getting worse?

At Maximum Progress, Max Tabarrok looked at every non-stop flight in the US since 1987 to determine if flight delays were getting worse. He found that short delays have actually gotten less common, but only because airlines have lengthened the scheduled travel times of flights to give themselves more padding. Long delays (in excess of 90 minutes), on the other hand, have increased by a factor of four:

Now we have some explanation for the pattern we saw above. Within the same routes, flights are now about 10 minutes longer than they were in 1987, partly reflecting more frequent delays pulling up average flight times and partly due to slower cruising speeds for fuel saving.

Starting around 2008, Scheduled flight times began increasing even faster than actual ones, and are now 20 minutes longer than their 1987 pairs along the same routes. This divergence makes it look like far more flights are early in 2024 when in reality almost all flights are taking longer.

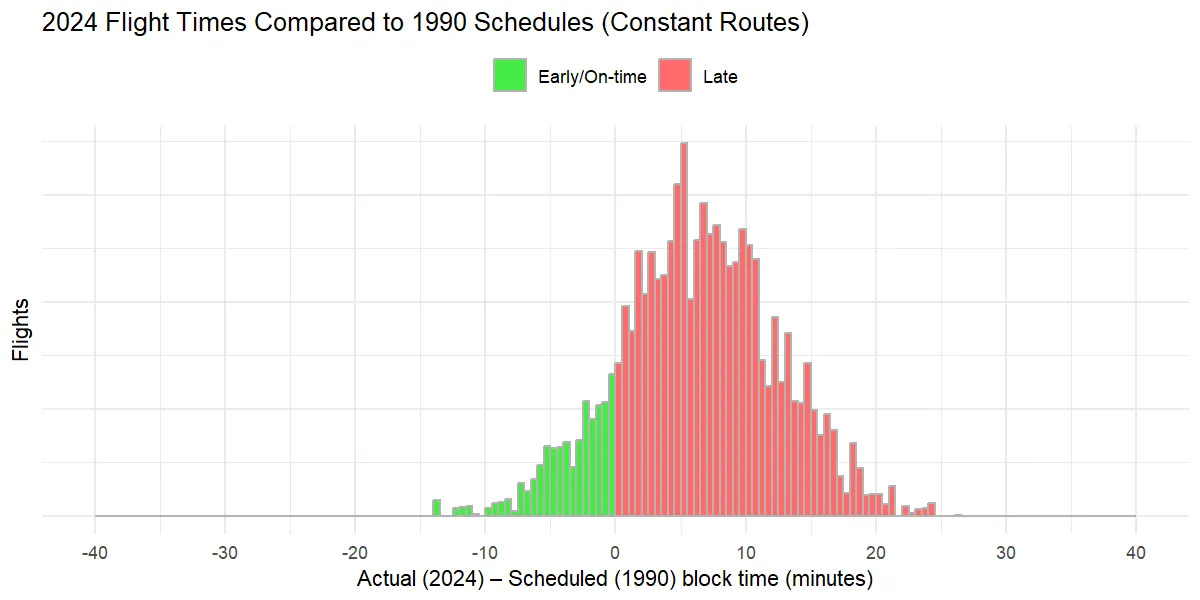

Similarly, if take all the routes in the 2024 graph and compare the actual flight time to the scheduled flight time on that same route in 1990, we see that most flights in 2024 are late by 1990 standards.

Max notes that adding 10 minutes to flights on average costs travelers around $6 billion a year, but I wonder if this change isn’t actually utility enhancing. Extending the scheduled trip time of flights, and thus making them longer but less likely to be late, probably means fewer missed connections, delayed meetings and other similar problems. Time spent traveling rises, but coordination failures decline, and the tradeoff might be worth it.

Ford goes unboxed

In September of last year, Tesla unveiled a novel car production process that it called “unboxed”. Rather than assemble the frame of the car and then attach components to it piece by piece on a conventional assembly line, the frame would be broken up into a series of large modules, each one built to a substantial level of completion before being attached together. Because less work would need to be done inside the already assembled car body, this would make the process more efficient. (We see a similar method of construction used in shipbuilding, adopted for similar reasons.)

Tesla has only partly begun to deploy its unboxed process, but it looks like Ford is going to attempt a similar production process for its new, low cost truck EV. Via Ars Technica:

Ford is splitting the production line into three. One assembles the front subassembly, another the rear subassembly, and the third the battery pack and interior, which then meet for final assembly. And it's moved to large single-piece castings for the front and rear subframe to allow this approach.

"There are other people that use large-scale castings but not in the way we do. We know of no one that has ever built a vehicle in three parts in this way and brought it together at the end," explained Field. "So it really goes way beyond a typical modular architecture that existing manufacturers have out there," he said.

"I don't think there's any platform that has been so blank-slate, architected around having a large subassembly that you can put a whole bunch of parts on," added Alan Clarke, executive director of advanced EV development.

3D printing advances

I’m always on the lookout for new, interesting manufacturing processes or capabilities, and I especially like seeing the boundaries of 3D printing/additive manufacturing being pushed. Here’s a paper where someone 3D printed an electric motor, using a special plastic that had iron fragments embedded in it. From the abstract:

This paper catalogues a series of experiments we conducted to explore how to 3D print a DC electric motor. The individual parts of the electric motor were 3D printed but assembled by hand. First, we focused on a rotor with soft magnetic properties, for which we adopted ProtoPastaTM, which is a commercial off-the-shelf PLA filament incorporating iron particles. Second, we focused on the stator permanent magnets, which were 3D printed through binder jetting. Third, we focused on the wire coils, for which we adopted a form of laminated object manufacture of copper wire. The chief challenge was in 3D printing the coils, because the winding density is crucial to the performance of the motor. We have demonstrated that DC electric motors can be 3D printed and assembled into a functional system. Although the performance was poor due to the wiring problem, we showed that the other 3D printing processes were consistent with high performance. Nevertheless, we demonstrated the principle of 3D printing electric motors.

And here’s a video describing a process called volumetric 3D printing. Conventional resin 3D printers use specific wavelengths of light to rapidly cure a light-sensitive resin layer by layer. Volumetric 3D printing uses a similar photo-sensitive resin, and rotates a container of it while projecting a specially-designed image onto it, which varies as the container rotates. As the light passes through the resin, it cures the resin in the shape of the object, printing it in just a few seconds.