Why Did Supersonic Airliners Fail?

(Note: Unless otherwise noted, quotes regarding American SST projects are from “High-Speed Dreams” by Erik Conway, and quotes regarding the Concorde are from “Concorde: New Shape in the Sky” by Kenneth Owen).

Progress in aviation has traditionally been associated with speed. Following the Wright Brothers’ flight in 1903, aircraft speeds steadily increased each decade, and increasing aircraft speeds was one of the primary goals of the National Advisory Committee for Aeronautics (NASA’s predecessor).

Even the sound barrier – the large increase in drag encountered by aircraft as they approach the speed of a sound wave in air – proved to be no match for the desire for increasing aircraft speeds. After the sound barrier was broken in 1947, a series of military jets capable of supersonic flight were developed and flown in the 1950s. It seemed obvious that civilian supersonic aircraft would follow shortly behind. Just as jet engines had displaced piston engines in commercial aircraft, so too would supersonic aircraft replace subsonic ones. It was the nature of aviation technology.

But this didn’t happen, though not for lack of trying. Since the late 1950s, there have been numerous plans to build a supersonic airliner. Most of them never got past the planning stages, and only two – the Soviet Tu-144 and the Concorde – were ultimately built and entered commercial service. Neither the Tu-144 or the Concorde were a commercial success, and today there are no supersonic aircraft in commercial service. Modern airliners fly at roughly the same speed as Boeing’s first jet airliner, the 707.

Despite billions of dollars in government investment, supersonic airliners remained noisier and less economical to operate than their subsonic competitors. Even while they were in service, they were a niche offering, effectively dependent on government subsidy to survive. Supersonic transport (SST) projects have thus far the unfortunate distinction of being some of the largest commercial failures in aviation history, though a new crop of aviation startups is hoping to change this.

Early supersonic aircraft

The sound barrier was first broken by a piloted aircraft in level flight in 1947 by Chuck Yeager in the rocket-powered Bell X-1.1 By the early 1950s, the US, Britain, and the Soviet Union had all developed jet fighters capable of supersonic flight (the F-100, the P.1 Lightning, and the Mig-19 respectively).2 But even before Yeager’s historic flight, people began to seriously consider the possibility of a supersonic commercial airliner – an article in Life magazine showed a design for a potential commercial SST sketched up by NACA researchers. But it was the development of the supersonic B-58 Hustler in 1956, followed by plans for the more advanced B-70 supersonic bomber, that truly kicked off SST development. The B-58 was the first bomber capable of Mach 2 flight. And while previous jet aircraft were capable of supersonic speed only for short bursts, the B-58 and B-70 would be capable of “supercruise” – flying almost their entire missions at supersonic speeds. The rapid development of supersonic capability in the 1950s made engineers optimistic that a potential SST could be in service as early as the 1960s.

In November 1956, just a few days before the first flight of the B-58, Britain’s Supersonic Transport Advisory Committee (STAC) met for the first time to study the feasibility of supersonic transport. Around the same time, Boeing began its own in-house SST study, and NACA formed an SST research group at the urging of a White House aviation advisor. The Soviets, too, were considering their own SST project around this time.

Ultimately the US, Britain (in partnership with France), and the Soviet Union would all pursue SST projects in the 1960s and 70s. These projects would be conceived with very different goals, and proceed along very different paths, but none would crack the fundamental economic challenges of supersonic travel, and commercial air travel would continue to be dominated by subsonic aircraft.

The British-French SST, Concorde

After forming in 1956, the British STAC met consistently over the next 3 years, putting forward its recommendations in a 1959 report. It concluded that an SST was feasible, and recommended development of two supersonic aircraft: a larger, Mach 1.8 aircraft for transatlantic routes, and a smaller, shorter-range Mach 1.2 aircraft for intercontinental travel. Mach 2 was chosen as the maximum speed to minimize technical difficulties: at that speed, existing aluminum alloys could be used for the aircraft structure. A Mach 3 aircraft was deemed technically possible but risky, since novel aircraft materials such as titanium would be required. It was estimated that the market might support anywhere from 150 to 500 aircraft, and that while initial costs would be higher than subsonic travel, advancing aerospace technology would steadily whittle away this difference. Development costs were estimated to be $210-270 million dollars for the larger aircraft (~$2-3 billion in 2024 dollars).

The committee recommended that SST development work should begin “without delay.” Waiting meant giving other countries the opportunity to pull ahead with their own SST programs, and possibly capture the market for supersonic aircraft, at great cost to Britain’s aircraft industry should SSTs become the new standard. At the time, Britain’s aircraft industry was struggling after a series of major failures. The Bristol Brabazon airliner had failed to attract any orders due to its high seat-mile costs, the enormous Saunders-Roe Princess flying boat was developed just as the flying boat era was ending, and the de Havilland Comet (the world’s first jet airliner) had been withdrawn from service after three crashes, ceding the jet airliner market to Boeing and Douglas in the process. To some, an SST represented the only chance for Britain to maintain an aircraft industry. Without it, the country would inevitably fall behind “first class powers” like the US. Upon receiving the report, the British Ministry of Transport opted to proceed with SST feasibility studies.

The fundamental challenge of supersonic travel is that air behaves very differently above and below the sound barrier, and different kinds of aircraft work best in each domain. At supersonic speeds, an aircraft works best if it's thin and needle-like, with narrow, swept back wings. But this sort of design has trouble providing sufficient lift at subsonic speeds. Similarly, different kinds of engines work better in each domain: at subsonic travel, a high-bypass turbofan works best, while at supersonic travel a turbojet is superior.

This makes designing an SST difficult, because it will inevitably spend significant amounts of time in both domains: cruising at supersonic speeds, but taking off, approaching, and landing at subsonic speeds (not to mention when abiding by restrictions on sonic booms over land). Designing an efficient supersonic aircraft is like designing a car that can double as a boat: it's possible, but it's hard to make such a vehicle as cheap as a conventional car.

As British researchers struggled with these tradeoffs, the most promising approach appeared to be the “slender delta”: a narrow triangular wing that was found to have good performance at supersonic speeds. Lift at lower speeds was an issue, but at low speeds and high angles of attack (when the aircraft “leans back”) the airflow over the wings could, with proper wing design, be made to separate, generating vortices over the wings which provided additional lift.3 Traditionally, flow separation in aircraft was avoided at all costs, but by taking advantage of it, a slender delta aircraft could have acceptable supersonic performance while still having sufficient lift at low speeds. Low-speed performance of a slender delta was tested on the HP 115 aircraft, and ultimately resulted in the Bristol 223 concept.

Wanting to defray the costs of development, Britain began to pursue a partner country to develop an SST with. Though it courted the US heavily, the US wasn’t interested in a collaboration. It had no interest in sharing what it believed to be its superior aerospace technology, and wanted to pursue its own SST project, which at a proposed speed of closer to Mach 3 was incompatible with British designs.

France proved more amenable. The French were working on a SST of their own, a successor to their Caravelle jet airliner dubbed the Super Caravelle, a slender delta Mach 2 aircraft that was similar in many ways to the proposed Bristol 223. In addition to sharing development costs, a partnership between Britain and France would help both countries. France would get access to British engine technology and the powerful Olympus engines that would make transatlantic supersonic flight possible; Britain would (it was hoped) be allowed to join the European Common Market, the predecessor to the EU.4 In 1962, the agreement was signed to combine their projects and develop two supersonic aircraft: the larger transatlantic aircraft and the smaller, shorter range Mach 1.2 craft (though this second aircraft would eventually be canceled). The agreement, critically, had no exit provisions, and had the status of international treaty: if either country withdrew, they could be sued in the International Court in the Hague, and be forced to pay hundreds of millions in restitution.

But despite joining forces, the two nations were pursuing the SST project for different reasons. Britain wanted to maintain its faltering aircraft industry, and wanted a grand symbol of Britain’s engineering and technological competence that would enhance national prestige, keeping Britain relevant in a world that was becoming dominated by the US and the Soviet Union. France, on the other hand, hoped to become more independent from America by fostering technological development: an SST project would require expanding French capabilities in materials, machining, electronics, and a host of other high-tech industries.5 France also saw the project as a chance to enhance national prestige. Neither country necessarily expected an SST to ultimately be commercially profitable, though economic concerns would loom larger and larger in Britain as development costs spiraled upward and the chance of recouping its investment dwindled. Only the binding nature of the agreement kept Britain from withdrawing from the project.

Building the Concorde was a monumental feat of aerospace engineering, on par in some ways with the Apollo program.6 Though military aircraft achieving supersonic flight had become common by the early 1960s, there was a world of difference between a military jet and a commercial airliner. Existing military jets flew at supersonic speeds for relatively short periods of time – as of 1963 no aircraft in the world had spent more than an hour at Mach 2 – but an airliner would have to maintain them for hours at a time, while keeping its passengers in relative comfort. And in many ways a commercial aircraft needed to be much more robust than a military jet: military jets had an expected lifetime of around 6,000 flight hours, while a commercial jet needed to be in service for at 30,000 flight hours to be practical. And even for military jets, breaking the sound barrier was far from routine, and catastrophic failure was common. One test pilot noted that while the US Air Force had purchased 128 B-58 Hustlers, by 1963 it was down to just 95 due to the high number of accidents.

And while most new commercial aircraft had the benefit of operating in a well-understood aerodynamic domain, the Concorde was venturing into uncharted territory. The vortex lift required for low-speed operation was novel, and until the full-sized Concorde actually flew, engineers weren’t sure whether it would work in practice. A new engine inlet system had to be invented, which used a carefully controlled series of ramps to reduce the speed of incoming air by 1,000 mph in just 14 feet, while simultaneously keeping a smooth, constant flow of air.

The Concorde also required a break from the historic method of aircraft design, where different aircraft functions (lift, propulsion, cargo, control) were performed by distinct components (wings, engines, fuselage and control surfaces). On the Concorde, meeting performance requirements required a much tighter integration between different parts of the aircraft, and a “new set of aerodynamic design principles." On typical airliners, for instance, small control surfaces called “trim tabs” compensate for differences between an aircraft's center of gravity and its center of lift. But at supersonic speeds, such control surfaces would produce an unacceptable amount of drag. Instead, the Concorde used a series of pumps to move fuel between different tanks to adjust the location of its center of gravity (the fuel was also designed to act as a heat sink, keeping the aircraft cool at supersonic speeds). Similarly, Concorde’s wing was cambered and twisted in such a way to keep the aircraft trim at cruising speed, eliminating the need for action from drag-inducing control surfaces.

These sorts of efforts were necessary because the Concorde had to hit a very narrow target to be viable as a commercial aircraft. Traveling at supersonic speed consumes about 5-7 times as much fuel as subsonic travel, and Concorde could only allocate around 6% of its total weight for passengers and cargo, compared to 20% on a Boeing 747 and 24% on modern jetliners. The tiniest decrease in aerodynamic efficiency would substantially reduce payload capacity. Concorde, in fact, was only just barely possible: had its range been even 2% less, it wouldn’t have been able to fly across the Atlantic.

All this development work and technological boundary-pushing came at enormous cost. And costs were amplified by the enormous amount of testing required. The primitive state of computers and aerodynamic theory in the 1960s meant that nearly every aspect of the aircraft required extensive verification using wind-tunnels and full-scale testing. The complex camber and twist of the wing, for instance, was found to be incorrect on the prototype aircraft, requiring the wing to be redesigned for the production aircraft. When the prototype had been completed, it underwent over 5,000 hours of flight testing, more than 3 times as much as the Boeing 747. Fatigue issues, the failure of a structural member well below its capacity due to repeated loading, were a constant threat on aircraft. Fatigue damage caused the Comet crashes in the early 1950s, and its risk was especially high on the Concorde due to high temperatures encountered at supersonic speeds. To verify there would be no serious fatigue damage, enormous test rigs were built in Britain and France to pressurize full-sized fuselages while repeatedly heating and cooling them.

And costs weren’t helped by the bi-national structure of the project, which added another layer of complexity. The chairman of the project alternated between Britain and France, two years at a time, and the work was split 50/50 as much as possible. Production lines were duplicated, at great expense, to have one in Britain and one in France. This 50/50 split, and the negotiation and horse-trading involved in trying to maintain it, was a continual problem on the project, resulting in delays, false starts and changes before reason (in most cases) prevailed”. Decision making was “incredibly torturous” – not-invented-here syndrome was a constant battle, and the need to come to absolute agreement on every aspect of the design slowed down the project considerably. Because responsibility for each portion of the project was divided between Britain and France, effectively no single person was in charge.7 And the tightly integrated nature of the design also made dividing work between subcontractors challenging. The intakes, engines, and nozzles, for instance, were a tightly coupled system, but each was the responsibility of separate companies, making it difficult to address problems when they occurred during testing. Some of the project leadership would later state that it was a miracle the project actually succeeded.

Poor conception of the project didn’t help the cost issue. The initial idea of two separate aircraft was eventually abandoned in 1964, but not before the second, smaller one absorbed significant design effort. And since the original plan was for each country to develop one aircraft (Britain the longer-range one and France the shorter range one), combining efforts meant reconceiving and redesigning the single remaining model until both countries agreed. As the project continued, Concorde’s weight grew (as happens to all aircraft during development), which required several additional redesigns and the adoption of different, more expensive construction methods and materials to reduce aircraft weight and achieve a reasonable payload capacity. This had the unfortunate effect of driving up the production costs and harming the already-marginal seat-mile costs of the aircraft.

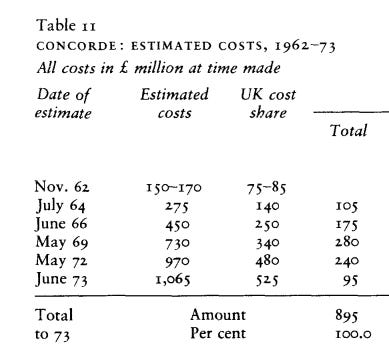

As costs crept up, and it became clear that the Concorde would never recover its development costs or possibly even operate profitably, the British began to regret participating in the project. Between 1962 and 1973, spending on the project increased by roughly a factor of five over initial estimates of 150-170 million pounds. But the treaty had no exit provisions, and the French, pursuing the project entirely for prestige and national development reasons, had no interest in canceling. Ultimately “French single-mindedness” carried the project through to completion, and Concorde first flew in March of 1969, just a few months before the launch of Apollo 11.

The American SST, Boeing 2707

Though interest was stirring in the US for an SST program in the late 50s, the American project took longer to get off the ground. Even the Soviet launch of Sputnik, which sparked an urgent need to redress the perceived loss of American technological superiority, wasn’t sufficient to kickstart an SST program. Following Sputnik, the Air Force put out a proposal for a SST project, but it was canceled when Eisenhower, in an attempt to reduce duplication of effort in the armed forces, removed the budget authority of the Army, Navy, and Air Force, putting it under the Secretary of Defense. Also canceled in this reorganization was North American’s XB-70 high-speed bomber program, which would have provided the technological basis needed for a commercial supersonic aircraft.

And while many felt developing an SST was an important national priority (pointing to rumors of a Soviet SST program), others were skeptical. The head of Lockheed’s famous Skunkworks, Kelly Johnson, thought little of the proposed SST, and the team at Douglas Aircraft warned the Air Force that developing an SST would require “virtually unlimited resources," and that there was no guarantee that it would be profitable to operate. And the aviation industry was not exactly clamoring for another expensive aircraft project. Aircraft manufacturers had nearly bankrupted themselves in developing commercial jetliners, and airlines were in dire financial straits paying for aircraft five times the cost of propellor planes they replaced.8

NASA research and other events related to supersonic flight also raised questions about the viability of an SST. While aerodynamic research in the 1950s resulted in better, more efficient aircraft configurations, expected payload capacities for an SST were very low, 7% or less of vehicle weight, with 50% of the weight devoted to fuel. An early sketch of a proposed SST at Douglas Aircraft showed a fuselage entirely filled with fuel, within which were passengers wearing diving suits, with a “no smoking sign” over their heads (Douglas would ultimately decline to participate in the American SST project). And while aviation technology in the US was typically first adopted in military aircraft, only later making its way into commercial service, the paucity of experience with extended supersonic flight meant that wouldn’t be possible with an SST. Rather than having the luxury of adopting vetted and robust technology, a commercial SST project would have to blaze a trail through unexplored territory, with all the risks and costs such development work entails.

American researchers were also much more concerned about sonic booms than the Concorde team was. The US military had been dealing with complaints from sonic booms since the mid-1950s, and early research suggested it was not something people would learn to accept. Sonic boom tests over the city of St. Louis in the early 1962 generated a significant number of complaints, with the local newspaper demanding the booming cease. 90% of residents interviewed felt the booms interfered with them in some way, and 35% found them annoying. When a B-58 set a speed record by traveling between New York and Los Angeles in 2 hours and 57 seconds (averaging just over Mach 1.5), it smashed windows and jammed police switchboards, ultimately resulting in over 10,000 complaints.

Ultimately, it was a new president, and the development of the Concorde, that spurred action on an American SST. In 1963 Pan Am placed a reservation for 6 Concordes, which was expected to spur other airlines to follow suit. This gave ammunition to pro-SST groups, who warned about lost national prestige and loss of the commercial aircraft market to foreign builders. John F. Kennedy, elected in 1960, also supported an SST, in part out of a desire to outdo Charles de Gaulle. Kennedy announced the American SST program on June 5th 1963, the day after Pan Am announced its orders for the Concorde. But though the US had committed to an SST project, concerns about profitability hadn’t been pushed aside nearly as much as they had on the other side of the Atlantic. Americans saw “little prestige in commercial failure," and economic considerations would dog the project throughout its lifetime.

The American SST program, led by the FAA, called for a 4,000 mile range, a 30,000 pound payload, and a speed of Mach 2.2 or greater — faster than Concorde and with a greater load capacity. But none of the initial submissions by Boeing, Lockheed, and North American Aviation met these requirements. Only Boeing came close: to overcome the fundamental challenge of needing different aircraft performance at subsonic and supersonic speeds, Boeing had proposed a complex “swing-wing” aircraft, with wings that would extend out at slow speeds for greater lift and then pull back into a delta-shape for supersonic travel.

And between the start of the program in 1963 and receiving the proposals in January of 1964, the base of support for an SST project had shifted. Kennedy had been assassinated, and while his successor Johnson supported the program, an advisory committee led by Defense Secretary Robert McNamara had been inserted between the FAA and the president. McNamara opposed the SST project: he felt that such a project was only justifiable if it would ultimately be profitable, and that it was clear that it never would be. McNamara was also cautious because of his knowledge of the A-12 project (better known by its successor, the SR-71 Blackbird), a secret high-altitude supersonic aircraft being developed by Lockheed for the CIA. The A-12 project was struggling; not only did it take “almost an act of God to get it off the ground”, but keeping it operational at high speeds proved to be enormously difficult, with CIA director John McCone reporting that “every notch we put it up above Mach 2 and every few thousand feet in altitude we run into a whole series of totally unforeseen problems.” The A-12 had been a year late for its first scheduled flight, and had constant struggles with its inlet control system (an enormously complex aerodynamic problem that would likewise consume a large amount of the time and resources on the Concorde project). It took a year and 66 flights for the A-12 to go from Mach 2 to Mach 3, and the first time it cruised at Mach 3.1, the aircraft’s wiring disintegrated and nearly all of the hydraulic fluid leaked out because of the extreme heat. As one of the only aircraft in the world capable of supersonic cruising, the struggles of the A-12 made McNamara skeptical that an SST could be developed on anything like a predictable schedule and reasonable budget.

Ultimately, McNamara’s strategy became one of delay, pushing back deadlines and putting off building prototypes in the hopes that aircraft technology would catch up in the interim and defuse the technical risk of the project.9 McNamara delayed selecting a winning proposal until the end of 1966 (though it was narrowed down to two airframe builders and two engine manufacturers), instead instructing participants to continue to refine their designs. But McNamara couldn’t delay forever, and at the end of 1966 Boeing’s swing-wing 2707 was selected over Lockheed’s L-2000 Concorde lookalike. Plans were made to proceed with prototype construction.

But Boeing’s proposal had been somewhat incomplete when it was selected, and as development continued, significant reworking was required. Weight crept up due to the addition of canards, structural stiffening and hydraulics, reducing its range to the point where it was unable to cross the Atlantic. Space for fuel required shifting the location of the wing’s swinging mechanisms, reducing its climb performance, which in turn required larger engines or larger wings, further exacerbating the weight problem. Ultimately, the design refused to “close”: the solution to a particular problem simply generated more problems in what seemed to be an unresolvable spiral.

Boeing ultimately went back to the drawing board, spending millions more engineering hours coming up with alternate designs. It ultimately selected a more conventional, lower-risk design without swing wings, the Boeing 2707-300, in October 1968, designed with a cruising speed of Mach 3 and a capacity of 250-300 passengers.

But while Boeing struggled to come up with a viable aircraft design, opposition to the SST project was building. Until the mid-1960s, criticism of the project had mostly been confined to the realm of government agencies and specialized technical organizations (airlines, aircraft manufacturers, and so on) concerned about the project’s economic and technical viability. But in the second half of the decade, opposition spilled into the public sphere, and the SST became a major political issue.

Initial public opposition stemmed from concern about the sonic boom. Sonic boom tests in Oklahoma City in 1964 yielded similar results to the earlier St. Louis tests, with 27% of the population stating that they could not accept repeated sonic booms. In 1967, physicist William Shurcliff founded the Citizen’s League Against the Sonic Boom, which by the end of the year had over 2,000 members. A book authored by Shurcliff, The SST and the Sonic Boom, sold over 150,000 copies after it debuted in 1970. Shurcliff, in turn, was able to convince major environmental groups such as the Sierra Club and the Wilderness Society that sonic booms represented a threat to natural wilderness, and enlist their support in opposing an SST. When David Brower, the Sierra Club’s executive director, resigned from the Club in 1969 and founded Friends of the Earth, one of its first major campaigns was to force the cancellation of the SST. In 1970, the Citizen’s League, Friends of the Earth, and 12 other organizations banded together to form the “Coalition Against the SST” (which later grew to encompass 31 organizations), which worked to turn public opinion against the SST project and force its cancellation.

As public opposition mounted, it was becoming clear within the SST project that the noise of the sonic boom would never be acceptable. Already there was significant opposition to jet engine noise, resulting in the creation of much more stringent jet engine noise requirements in 1968 (though supersonic aircraft were exempt from this regulation). By the late 1960s there was discussion by the FAA and President Nixon of banning the sonic boom, and civilian supersonic travel over land would ultimately be banned by the FAA in 1973. For the foreseeable future, SSTs would only go supersonic over water.

But this didn’t dissuade opponents to the project, who still considered the project an environmental and economic disaster. Even aside from the sonic boom, the engines of an SST would have great difficulty meeting the latest FAA noise requirements, and new research suggested that a fleet of SSTs might be a threat to the ozone layer. The shaky economics of the program led many to question why the government was spending money on a project that could be better spent elsewhere. It did not escape notice that Boeing, convinced of the commercial possibilities of the 747, had entirely footed the bill for its development, but had opposed contributing even 25% of the funds for the SST project. Statements from 16 prestigious economists, including Milton Friedman, Kenneth Arrow, Paul Samuelson, Robert Solow, and W.J Baumol, all expressed their reservations about the SST.

For many environmentalists, however, the importance of opposing the SST was symbolic. The SST represented “worship of technology for its own sake”, a project chosen by government technocrats that would absorb billions of government dollars and cause enormous environmental harm catering to needs of the ultra-wealthy that could afford to use it. Many environmentalists, such as David Brower, wanted to abandon the pursuit of progress for progress’ sake that had led to widespread environmental devastation, and redirect technological development towards goals that were beneficial to humankind and the natural world. For them, stopping the SST was a crucial victory in this larger war.

Anti-SST opposition succeeded in making the project a major public issue, and generated a storm of negative media coverage (which was countered to some degree by a retrenchment of pro-SST groups). The first Earth Day in 1970 marked an enormous outpouring of anti-SST activism, with teach-ins, public speeches, and demonstrations against the project, driving opposition to it to new heights. But unbeknownst to the environmental lobby, by the time the SST became a major public issue it was effectively already dead. In late 1969, the DOT told Boeing that it would be required to meet a new, more stringent noise standard, 12 decibels lower than previous requirements. Achieving this would require a new, heavier engine and wing, increasing the aircraft's weight and further driving down its already marginal economics. The SST was now expected to weigh 100,000 more pounds than the 747, carry 2/3rds the passengers, while costing twice as much to buy and much more to operate. The economics of it had deteriorated so severely that Boeing told the DOT it no longer planned to bring the aircraft into production, and that any subsequent changes would need to be entirely funded by the government.

Ultimately, the American SST project was canceled in 1971, after the House and Senate, under significant public pressure, voted to cancel additional funding for the project. And though over $800 million ($6 billion in 2024 dollars) was spent on the project, no aircraft was ever produced, save for a large wooden mockup of the Boeing 2707, which is currently in storage at the Museum of Flight in Seattle.

The Soviet SST, Tupolev Tu-144

Like Britain and the US, the Soviet Union had been considering the possibilities of supersonic airliners since shortly after the sound barrier had been broken. In some ways, the Soviet Union was the perfect country for incubating an SST project. Its centrally-planned economy meant that aircraft designers were, at least initially, free from concerns about seat-mile costs, fuel consumption rates, or other measures of economic efficiency. The major impetus for an SST, along with ideas of national prestige which propped up every other SST project, was time savings in crossing the enormous distances of the Soviet Union (which stretched almost 7,000 miles from east to west. Soviet leadership fervently believed in the power of advancing technology, and had already made impressive gains in aerospace technology: not only in the space program, but also in things like the Tu-104 jetliner (for a time the only operating jetliner in the world after the Comet was withdrawn from service) and the Tu-114 (the largest, fastest, and longest-range propeller passenger plane in the world when it was introduced). The Soviet Union was all too aware that the West was developing SSTs, and did not intend to be left behind. The Soviet SST program, which would result in the Tupolev Tu-144, officially kicked off in July of 1963, a month after Kennedy announced the American SST program.

The Soviet’s relatively limited experience with supersonic aircraft meant that the Soviet SST would end up borrowing many ideas from Western aircraft, such as the narrow delta wing. The Tu-144 would end up bearing a striking resemblance to the Concorde, with both aircraft having a slender delta wing, no tails, and a drooping nose, resulting in the Tu-144 being nicknamed “Konkordski." The Soviets did in fact spend significant time and effort trying to illicitly obtain information on the Concorde project, going so far as to bribe French airport maintenance crews to supply them with Concorde tire debris, and (allegedly) walking around with special sticky-soled shoes at Concorde assembly locations in the hopes of picking up fragments of exotic alloys.

But though it ended up closely resembling the Concorde, the Tu-144 differed from it in many ways, mostly for the worse.10 Both aircraft, for instance, used afterburners, which inject fuel into the engine’s exhaust stream, increasing power at the expense of greatly increased fuel consumption. But while the Concorde only used afterburners on takeoff, the Tu-144 required afterburners to be used continuously, giving it a dismal range of just 1600 miles compared to the Concorde’s range of over 4,000 miles (later engine improvements extended the Tu-144’s range to closer to 3,300 miles, still substantially less than Concorde). The Tu-144 lacked the Concorde’s twisted and cambered “self-trimming” wing, and also its advanced system of engine inlets. The Tu-144 didn’t use fuel as a heat sink, instead opting for enormous air conditioners that created a deafening roar in the passenger cabin (so loud that passengers had to communicate by passing notes), though it did use fuel pumping to move the aircraft's center of gravity as Concorde did. In contrast to the luxury accommodations of the Concorde, the Tu-144 never managed to move its passengers in anything resembling comfort, subjecting them to noise and vibration more similar to military aircraft.

But for all its lack of aerodynamic refinements, the Tu-144 was developed impressively quickly, especially given that the Soviets needed to solve many of the same aerodynamic and fabrication difficulties that Concorde did. From kicking off in 1963, the Tu-144 made its first flight in December 1968, several months ahead of Concorde. The Soviets had once again come in first in a race to deploy advanced aerospace technology.

The Concorde and the Tu-144 in Service

In the face of environmental opposition, and with the chance of ever producing a profitable aircraft receding, the Americans bowed out of the SST race in 1971. The subsequent experience of the Tu-144 and the Concorde would confirm both the dismal economics and the serious environmental issues, particularly noise, of supersonic transport.

By the end of the 1960s, it was becoming clear that supersonic flight over land would largely be untenable, greatly reducing the proposed market for the Concorde. Nevertheless, British Aircraft Corporation still projected a market of up to 200-250 Concordes, and at one point options to purchase totaled more than 100 aircraft. But by the time the Concorde entered commercial service in 1976, its prospects were considerably dimmer. The Oil Crisis had driven up the cost of jet fuel, and the Boeing 747 had driven down the cost of transatlantic flight. Its speed notwithstanding, the Concorde was twice as expensive to buy and twice as expensive to operate as a 747, for an aircraft with around 1/4th the passenger capacity. Ultimately nearly every airline canceled its orders, and the Concordes were only adopted by the captive state airlines of Britain and France (British Airways and Air France, respectively), “sold” at a steep discount to their production cost. Rather than hundreds of aircraft, a mere 14 Concordes entered service.

Not only was this far below the number of sales needed to recoup development costs, but neither airline was able to operate their Concordes profitably. In their first five years of operation, Concorde operations lost money at both airlines nearly every single year. Even ignoring depreciation costs (ie: the allocated cost of purchasing the aircraft) wasn’t enough to put Concorde operations in the black. Fleetwide, Concordes were operating an average of just 2.6 hours per day for British Airways, far less than the 7.5 hours per day expected. Only one route – London to New York – was profitable, with every other route losing money. In 1979, the British and French governments gave up trying to sell Concordes (though not before spending half a billion dollars on an enormous marketing campaign), and shut down the assembly lines and destroyed the tooling for making them.

On top of its poor economics, Concorde was never able to fully resolve its noise issues, either the sonic boom or engine noise at subsonic speeds. Concorde service to the US was delayed by widespread protests over the sonic boom, and in some cases (such as at New York City airports) the aircraft was initially banned from landing.11 In subsonic operations its engines remained especially noisy compared to contemporary turbofans, despite the Concorde team spending millions on noise abatement research (it was eventually found that noise suppressors would have such a negative impact on fuel consumption and range that even if one were developed, it wouldn’t be possible to use it.

Ultimately Concorde would continue operating until 2003. British Airways eventually found a way to operate it profitably by cutting all routes except the New York-London route (along with the occasional charter flight), increasing the ticket price, and cutting what had become extraneous overhead costs. Additional fatigue testing, for instance, was found to be unnecessary, since the Concordes were flying so infrequently that they had already been tested past their likely service lives. But this “profitability” was something of an accounting trick, as it required ignoring both the upfront development costs and the actual purchase costs of the aircraft. And even then, Concorde still required twice as much maintenance, and flew at much lower load factors, than other commercial aircraft.

The beginning of the end of Concorde service was marked by an Air France crash in 2000, which took every Concorde out of service while the causes were investigated. Once the causes were understood and the remaining Concordes retrofitted to prevent similar accidents in the future, they returned to service – on September 11th, 2001. Following the terrorist attacks, air travel declined significantly, as did Concorde’s profits. The French, who had never had as much success operating Concorde profitably as British Airways, wanted to end their Concorde service, and British Airways, faced with the near doubling of maintenance and spare parts costs such a withdrawal would cause, had no choice but to end their Concorde service as well. The final flight of Concorde was in November of 2003.

The Tu-144 had even less success commercially. After a 1973 airshow crash, the Tu-144 faced increasing bureaucratic opposition internally, with many wondering whether the resources being invested in the project could be better spent elsewhere. The Tu-144 had a short range, an uncomfortable cabin, and consumed such enormous amounts of fuel that even the Soviets couldn’t ignore it. Russia’s state-owned airline Aeroflot quietly canceled its (already greatly reduced) Tu-144 service in 1983, with the director of Aeroflot's operations later stating that it had become too expensive to run.

Subsequent SST projects

But the dream of an SST didn’t stop with the Concorde or the Tu-144. Proposals for a new generation of SSTs continued to be floated (though none turned into an actual aircraft). In Europe, there were plans to upgrade future Concordes to a more advanced “B” model that were never brought to fruition, and in the 1990s a study group was formed to investigate a potential “Concorde 2” (ultimately abandoned in favor of a “very large transport” project which became the Airbus A380). In the US, NASA formed an “Advanced Supersonic Transport” (AST) program almost as soon as the SST project was canceled, to try and build the technological foundation for a future SST. This work continued through the 1970s, later transforming into the Supersonic Cruise Aircraft Research (SCAR) program, but was ultimately canceled in 1981. The poor economic performance of Concorde, and the lack of aircraft manufacturer support whittled away political support for funding the technological development needed for another SST program.

A more robust US SST program began in 1986, after Reagan announced the idea of a “new Orient Express," a Mach 25 hypersonic aircraft that could fly from New York to Tokyo in just two hours, which was followed by announcements of hypersonic programs in Britain, Germany, and Japan. But it soon became clear that a Mach 25 aircraft made little sense: even a Mach 8 aircraft would spend most of its time accelerating or decelerating (in the words of one engineer, “the world turned out to be too small for a Mach 25 airliner – or even a Mach 6 one”). The program thus evolved into a more modest “High Speed Civil Transport” program to develop an SST with a speed below Mach 5. Early studies showed that an economic SST with a speed between Mach 2 and Mach 3.2 could be viable as early as 2000. Subsequent research showed that the still-concerning ozone problem could be addressed, and that an engine could be built to meet then-current Stage 3 noise standards required by the FAA. Sonic booms would remain an issue (research suggested that efforts to reduce the noise from a sonic boom would make an aircraft uneconomical), but it was believed that there was a large enough market purely for over-water SST routes.

Boeing, McDonnell-Douglas, GE and Pratt & Whitney were engaged to develop the technology for a 300-passenger, 5,000 mile range, Mach 2.4 SST that would be economically competitive with year 2000 subsonic aircraft. It was not, technically, an aircraft development program, but rather a technology research program to build the foundation for a subsequent aircraft. Efforts included high-temperature carbon-fiber composites, fuel-tank sealants, and more advanced supersonic engines.

As the program proceeded, much successful research was generated. However, as timelines stretched out, the issue of noise once again became a limiting factor. While it appeared possible to built an SST that would meet the Stage 3 noise requirements in place when the project began, noise requirements were steadily getting more stringent, and meeting the requirements that were likely to be in place when the aircraft was likely to first be in service couldn’t be accommodated by the program’s technologies. Similarly, the proposed aircraft struggled to remain competitive with the seat-mile costs of existing aircraft. The High-Speed Research program was ultimately cancelled in 1999, though many of the technologies it developed (such as new turbine blade materials) have since been used successfully in other areas.

The Future of an SST

Today, commercial airliners are still traveling below the speed of sound, but there’s a whole new crop of companies trying to find feasible ways around the sound barrier. This includes companies like Boom (developing a “conventional” supersonic transport), Hermeus (developing hypersonic Mach 5 aircraft), Venus Aerospace (developing a “rotating detonation rocket engine” that will carry passengers at up to Mach 9), and Astro Mechanica (building an electric-adaptive Jet Engine).

It’s not yet clear whether this crop of aerospace companies will succeed. On the one hand, the aerospace landscape has changed significantly since the first SSTs were developed in the 1960s. Supersonic aircraft performance is much better understood, and advances in computational fluid dynamics and optimization techniques mean much more design can be done on the computer without requiring expensive wind-tunnel testing. Engine performance has steadily increased, and materials like high-temperature carbon fiber have become available. And the steady increase in air traffic since the Concorde debuted also means there’s potentially many more customers, and many more viable routes for supersonic travel than there have historically been (though as late as 2003, the Concorde had trouble even filling its New York-London route to capacity). It's far easier to build a supersonic aircraft today than it was in the 1960s, and there are potentially many more customers for one.

But some things haven’t changed. It’s still incredibly risky to develop a new commercial aircraft, as billions of dollars need to be recouped from a relatively small number of sales. This is difficult even for a “conventional” aircraft, much less one traveling at supersonic speeds, which likely has a much smaller number of aircraft to recover development costs on (there’s a reason that Boom was unable to get any of the Big 3 jet engine suppliers to build them an engine). Supersonic travel still burns far more fuel than subsonic travel does, and a sonic boom drastically limits the routes it can travel (though there’s some promising research from NASA on reducing sonic booms).

And the nature of supersonic flight, where significant amount of time is spent on both subsonic and supersonic domains, means trying to find a way to build an aircraft that is “two aircraft in one," or simply accepting a performance penalty with an airframe/engine that is not optimized for a particular domain. Astro Mechanica is pursuing the former strategy, with its electric-adaptive engine that can theoretically be made very efficient at drastically different aircraft speeds. Boom is pursuing the latter strategy, using a more traditional turbofan that will be quiet and efficient at low speeds, at the cost of reduced supersonic performance. Supersonic aircraft are still noisier than conventional commercial aircraft, and people still hate aircraft noise, causing the noise requirements for them to continue to get stricter. And supersonic aircraft still have a very narrow performance target they must try and hit to be economical, much less pay back their development costs.

Conclusion

Ultimately the SST projects are a story about the limits of the “push” strategy of technological development. With new technologies, it's often hoped that with enough upfront investment, technical issues can be resolved, and they can be pushed far enough down the learning curve to the point where they become economically competitive and widely adopted. This is, indeed, often possible: both Solar PV and wind turbines absorbed a large amount of government dollars in the form of R&D investments, Feed-In Tariffs, and Renewable Portfolio Standards, which pushed it far enough down the learning curve that they have become one of the cheapest sources of electricity, and they’re still getting cheaper.

But such a strategy requires some cooperation with the universe. To succeed, a technology needs to contain the potential for sufficient improvement based on the form it takes, the phenomena it leverages, and how it compares to competing technologies. Some barriers are too big to be pushed through by sheer force of will. The US, Britain, France, and the Soviet Union spent billions of dollars and millions of man-hours in an unsuccessful attempt to continue the trend of increasing commercial air travel speeds. The fundamental physical constraints of supersonic flight have made it inherently noisier and more expensive than subsonic travel, which combined have doomed most commercial efforts, regardless of how many dollars were thrown at the problem. We saw a similar phenomenon with titanium, which despite its abundance, its useful physical properties, and expectations that it might displace steel or aluminum, remains comparatively niche. Despite huge government investments, it remains a comparatively niche material because of fundamental physical constraints that make smelting and processing it expensive.

Technology may ultimately resolve these issues, by overcoming previous physical limits, or driving down input costs to the point of irrelevancy. Cheap enough fuel would make the high fuel burn of supersonic aircraft irrelevant. A clever design that sufficiently reduces a sonic boom could open up enough new routes to drastically increase the number of aircraft expected to sell. But these types of breakthroughs aren’t guaranteed, even if enormous sums are spent on them.

SSTs are also a story about the importance of the context that surrounds a technology: a changing landscape can drastically alter how attractive a technology appears, even if nothing about the technology itself changes. When the first SST projects were being conceived, there was nothing resembling the modern environmental movement, no aircraft noise restrictions were in place, and air travel was still comparatively expensive. By the time they entered service, all this had changed: environmental concerns had drastically shifted what sorts of technology were acceptable, people had become fiercely opposed to noisy aircraft, and competing methods of air travel offered far superior economics. A similar evolution took place with the HSCT program in the 1990s. Supersonic airliners could go faster than 1,000 miles per hour, but they still had trouble hitting the moving target of a changing world.

If you’re interested in reading more about supersonic aircraft, an SST reading list is available here for paid subscribers.

Prior to this, aircraft had broken the sound barrier only in dives, and unpiloted craft like the V-2 had broken it as well.

The prototype P.1 Lightning was capable of supercruise, but not the production models.

The high-angle of attack at low speeds limited pilot visibility. This was solved by having a nose that would drop down during takeoff and landing, giving the Concorde its distinctive “droop snoot.”

This didn’t work, and French president Charles de Gaulle would deny Britain membership to the Common Market a few months later.

This same impulse of technological independence would lead France to build its nuclear reactor fleet.

Neil Armstrong would later state that “from a technical perspective...the Concorde was as big a challenge as putting a man on the moon.”

This torturous decision making, however, has been credited with the Concorde’s excellent design: because the British were constantly shooting down French ideas and vice versa, only the most bulletproof design ideas could pass muster.

As late as 1963 it was believed that no aircraft manufacturer had made a profit off commercial jets.

The FAA administrator Najeeb Halaby, on the other hand, believed that only by constructing an actual aircraft and learning about its characteristics during flight could progress on the project be made.

The differences weren’t all in favor of Concorde. The Tu-144’s turbofan engines, for instance, meant it was quieter than the Concorde, which used turbojets.

This ban was eventually overturned by a Supreme Court ruling in 1977.

A great many of the phenomena this newsletter discusses can be explained by the "project/product" dichotomy. Some fields of endeavor just remain stuck in the "project" phase of the learning curve, in which everything is boutique and production too small-scale to learn and improve by iterating endlessly, let alone to defray the upfront costs of tooling and capital plant.

Cars and appliances bridged that gap pretty quickly after their inception, with some government support in the form of road-building and rural/public electrification. Semiconductors got there with a greater proportion of government support (if I recall correctly the Apollo Program was the single largest global consumer of integrated circuits in the 1960's) and then took on a life of their own as commercial applications emerged widely in response to falling costs, as did solar PV.

Conventional commercial aircraft are *just barely* close enough to a mass market product that jetliners can be produced (somewhat) profitably by a handful of firms with lots of hiccups and screw-ups and ongoing government subsidy in the form of military R&D and contracting.

Supersonic civil aircraft are not, at present, a mass market. They have the potential to one day become a mass market, but only if someone gets basically every decision in the development tree right while operating on a relative shoestring of venture capital funding, so that the first "project" iteration of the eventual "product" shows sufficient promise to justify continued investment.

I don't know enough to guess what the chances of that are, but I can't see them being very good for any individual effort.

I have maintained that SST is made obsolete by wifi on planes