Should US homebuilders emulate Sweden?

A common sentiment I see with folks interested in improving US homebuilding is that we should try and emulate Sweden. More specifically, that we should emulate Sweden’s large-scale adoption of prefabricated construction. Something like 85% of Swedish single family homes, along with 30-40% of multifamily buildings, are factory-built, produced in large, impressive-looking factories like Lindbäcks. Per this line of thinking, the main problem with US housing construction is that it’s still done on-site instead of within a more efficient factory, and Sweden shows that it’s possible for prefabrication to be the primary method of home construction. Here, for instance, is this idea being discussed by governor of California Gavin Newsom on a recent episode of the Ezra Klein show:

Ezra: I want to slow down what you just said here, just for people who are not as into the modular housing debate as we are.

Ezra: So right now, building housing is: Guys show up with hammers.

Gavin: Same way they have been since the beginning of time.

Ezra: This is why productivity is down.

Gavin: Yes.

Ezra: There’s no place in America that does a ton of off-site manufactured housing. But in Sweden, I think more than 80 percent of single family homes are now off-site manufactured. You can have modular build, as many places do, in unionized factories.

Gavin: That’s right.

According to this theory, prefab is like lots of other US building practices such as transit construction or elevator installation: we simply need to adopt the best practices that are already being successfully used in Europe.

I think Swedish prefab construction is impressive, and there’s undoubtedly things US builders can learn from it. But for single family home construction, I don’t see much evidence that prefab has been particularly helpful in improving construction productivity, or driving down building costs. For multifamily, the evidence that prefab is helping drive cost savings is somewhat better, though I’m not particularly confident of that.

Swedish construction statistics

One nice thing about Sweden is that the government provides a lot of statistics on various aspects of the construction industry. The government provides both a construction cost index (which tracks the cost of inputs to single and multifamily construction, such as materials and labor), and a building price index (which tracks the price of completed single family homes and multifamily apartment buildings). Each of these are graphed below. For comparison, I’ve also included the US Census single family home index (which is a pretty good proxy for trends in overall US construction costs), and the US and Swedish Consumer Price Index.

And to focus on more recent trends, here’s the data since 1995:

We can see that, as in the US, Swedish construction costs and prices for residential construction have risen faster than overall inflation. What’s more, since 1995 Swedish construction costs have risen at about the same rate as the price of US single family homes, but prices have risen much faster. This does not suggest to me that prefabricated construction has enabled substantial cost savings or productivity improvements.

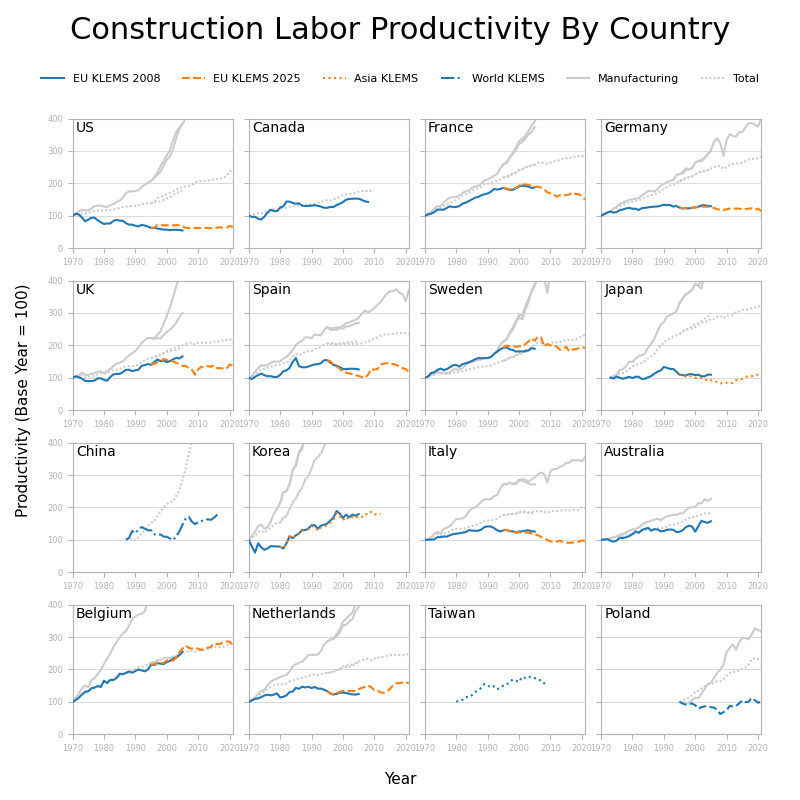

Similarly, when we looked at Swedish KLEMS data, which tracks industry-wide productivity statistics, we noted that while Swedish construction productivity was improving from the 1970s to the mid-1990s (a trend that was mirrored in many other European countries), since then productivity growth has been stagnant, even as prefab adoption has continued to rise. Again, this is not what I’d expect to see if prefabrication were driving substantial productivity improvements.

These are somewhat abstract measures, and high-level productivity estimates are always fraught. But we see the same thing if we look at actual building prices. Below are the price per unit area for Swedish single family and multi family homes, compared to average selling price per unit area for US single family homes. All values have been normalized to 1998 = 100, and exclude the cost of land.

Since 1998, the price per unit area of Swedish homes (both single family and multifamily) has risen slightly faster than the average price of US single family homes. In fact, per Statistics Sweden, the average price of a new Swedish single family home was around $286 per square foot in 2023, compared to $166 per square foot in the US, more than 70% more.

If you read between the lines of comments by Swedish prefab companies, they admit that their factory-based methods aren’t particularly inexpensive. In this article about Swedish prefab in the New York Times, an executive at Lindbäcks basically admits that their build costs will be higher than conventional builders, but that they might make it up in other ways:

Building quality homes, whether on-site or off-site, will never be cheap. You don’t want to scrimp on materials or labor, and the savings of factory-built homes might not be obvious at the start, Lindbäck told our group. A conventional builder might bid lower than Lindbäcks, but then there are the costs of supervising the construction on-site and paying for delays in interest charges. And conventional builders profit from changes late in the process.

With factory-built houses, modifications are minimized because customers generally select from a standardized framework and changes are allowed only up to a certain point. The factory builder’s advantage is quality control and speed. Real profit, long-term profit, comes from streamlining the building system for predictable outcomes and fast delivery.

One thing that is notable to me, however, is that Sweden’s multifamily prices per unit area were roughly flat between 2017 and 2023, even as costs were rising.1 Without knowing more it’s hard to lay this entirely on the feet of prefabrication, since a fairly large fraction of Swedish multifamily projects have significant amounts of on-site work, and many things could be behind prices staying flat. But it nevertheless seems telling.2

Swedish vs US build quality

When I mention the high build costs of Swedish houses compared to US ones, the most common response I get is that Swedish houses are built much better than US houses: specifically, folks will typically point out the much greater energy efficiency of Swedish houses. One architect stated that it would cost US builders several hundred dollars per square foot to achieve the level of energy efficiency that Swedish homes achieve for much less.

I’m not an expert on building energy efficiency (and I refuse to become one), but as far as I know it’s true that Swedish homes are much more energy efficient than the typical US home. Here’s a Youtube video series explaining the many construction differences between Swedish and US homes which allow the former to achieve much greater energy performance. However, I do not find this argument particularly compelling.

For one, the promise of factory-built construction is that it should achieve better quality AND greater productivity/lower costs, not trading off one against the other. Ford’s assembly line was transformative because it allowed Ford to produce a car that was higher quality, more reliable, AND cheaper than the cars made by other manufacturers.

But I’m also somewhat dubious of the idea that US homes would be much more expensive than Swedish homes if they were built to the same level of energy performance, and that Swedish prefab is efficiency improving/cost saving once you take this into account. The strictest energy efficiency standard I’m aware of (in Europe or anywhere else) is Passive House/Passivhaus, which demands an extremely tight building envelope and high levels of insulation to achieve an extremely small amount of energy consumed for heating and cooling. Passive House-built homes use something like 80-90% less energy for heating than conventionally built homes in the US, and (as I understand it) Passive House is a stricter standard than Sweden’s energy efficiency code requirements.

Unsurprisingly, there’s a cost premium for building to Passive House standards, but as far as I’m aware it’s a lot less than you might expect. Most estimates I’ve seen place the Passive House premium at around 5-20% over conventional US construction, provided you get an experienced builder. One survey of multifamily buildings in Massachusetts and New York found an average Passive House cost premium of just 3.5% compared to conventional construction. Here’s a Passive House single family home that was built in Rhode Island for $163 per square foot in 2018, using “everyday materials and methods.” Here’s another one that was built in Pennsylvania for $165 per square foot, also in 2018. That’s higher than average US prices in 2018 (which were around $114 per square foot), but it’s only a little above average prices in the Northeast (which were $155 per square foot). Per Statistics Sweden, average Swedish prices were about $265 per square foot that same year.3

Conclusion

Lower costs and greater productivity isn’t the only reason you might want to move to a factory-based construction model. Being able to pick a home out of a catalog and knowing exactly what you’re going to get and what the price is going to be is a big benefit for homebuyers. Reducing the amount of on-site time is often an attractive proposition, especially if you’re building somewhere cold (like Sweden!). There are good reasons to use prefab.

But for single family home construction, I don’t see much evidence that Sweden has been able to use prefabricated construction to drive substantial efficiencies or cost reductions in the building process. Essentially every productivity or cost metric over the last 30 years shows Sweden looking at best similar to the US, and often looking worse. Average Swedish single family home costs per square foot are substantially higher than in the US. Higher energy efficiency of Swedish homes can partly explain this, but the idea that Swedish prefabrication is more efficient/cheaper once you take this into account seems hard to defend.

For multifamily construction, the evidence is slightly stronger that there are some cost/efficiency benefits to prefab, but it still seems highly uncertain to me.

Interestingly, if you first convert to USD, you get a significant decline in the price of Swedish multifamily housing per unit area, due to fluctuating exchange rates.

I was also recently pointed to this paper, which tries to look at productivity and cost improvement in multifamily construction in Sweden, and finds some suggestive evidence pointing to prefab being cheaper and more productive than conventional construction. There are some issues with this paper — for one, there’s no real attempt to control for various factors that might influence construction costs like location, project complexity, etc. — so I’m not currently weighing it particularly heavily, but it seems worth noting at least.

One possible response here is that Sweden is much colder than the US, which might cash out to higher construction costs, so that comparing US average prices with Swedish average prices is misleading. But the US midwest is fairly cold (Minneapolis has a similar climate to Stockholm), and actually has lower prices per square foot than the US average.

Just a speculation, but I wonder how much underground parking increases Swedish multifamily construction costs. In my travels in Europe I am struck by the extent (almost universality) of underground parking, especially in colder climates. Obviously building underground parking is more expensive than just laying down some asphalt outside.

I would also lean into the 'Swedish housing is higher quality' argument. Not just the outside windows & doors, but solid-core interior doors, soundproofing, structural integrity - is it my imagination or does European modern construction just feel more solid, more durable, thicker, quieter, more substantial than American?

Also, it would be interesting to compare long-term (30+ years) energy, repair & maintenance costs. My hunch is that in Sweden you pay more up front but less over time.

I can give you a very relevant, current project to chew on. I'm the project manager for a city in New Hampshire, USA, where the city wants to do a workforce housing demonstration project on city owned land. We are building six (6) 1,000 square foot, two-story cottages on about a half-acre, arranged around a shared central court, with parking in a nearby shared lot. The city wants to sell these to city employees at cost. We are using modular homes (not manufactured mobile homes), each consisting of two modules. We are struggling to get this project to less than $425,000 USD per home.

The city is its own contractor -- we bid out every sub trade and eliminated the profit factor that would have been in play had we gone with a general contractor.

We tried bidding out the modular units, but that's a problem in New England. There are three modular manufacturers in New England and one in upstate New York. There are several in Canada, but we found that logistics, shipping costs, and tariff concerns made those uncompetitive. Only one of the US manufacturers provided a bid. The others are way too busy, with most of their modules going to large multi-family projects.

I can state with confidence that a good modular manufacturer can set a less expensive structure, and at better quality, on a given foundation. They can control the cost inputs far better than an on-site builder can. But here's why the eventual home won't be any less expensive that a stick built one:

THE HOME WILL SELL FOR THE LOCAL MARKET PRICE, NO MATTER HOW IT WAS BUILT.

The builder is not going to pass on the savings the builder realized by using modular construction. Why give profit away? You might suggest that if you bid out the house, the one using the modules will be able to underbid stick builders. But here's why this does not work:

OWNERS RARELY, IF AT ALL, BID OUT THE CONSTRUCTON OF A NEW HOUSE.

No, owners will find a contractor with a good reputation, who can fit the owner's home into the contractor's schedule, and who seems to be a good fit for the owner. That's how homebuilders are predominantly chosen.

It's no wonder that the cost of construction is what it is. Aside from the materials costs, there's essentially little competition among builders. If there were more modular manufacturers, and more hungry builders, then maybe we'd see prices stabilize.

What I think the federal and state governments need to do is actively help new modular manufacturers get set up. That assistance can take many forms and will cost money, but I'd rather spend money this way than giving out housing assistance. Secondly, government should be spending a lot more money on growing the construction trades and educating small time builders on how to be better businesses. This will take time, so thirdly, congress needs to get their act together and immediately put in place some sort of work permit system that would enable immigrants to work in the trades here legally, perhaps giving them a path to citizenship after five years of steady work and good behavior.

Tim in New Hampshire